Pot magnets with internal thread

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

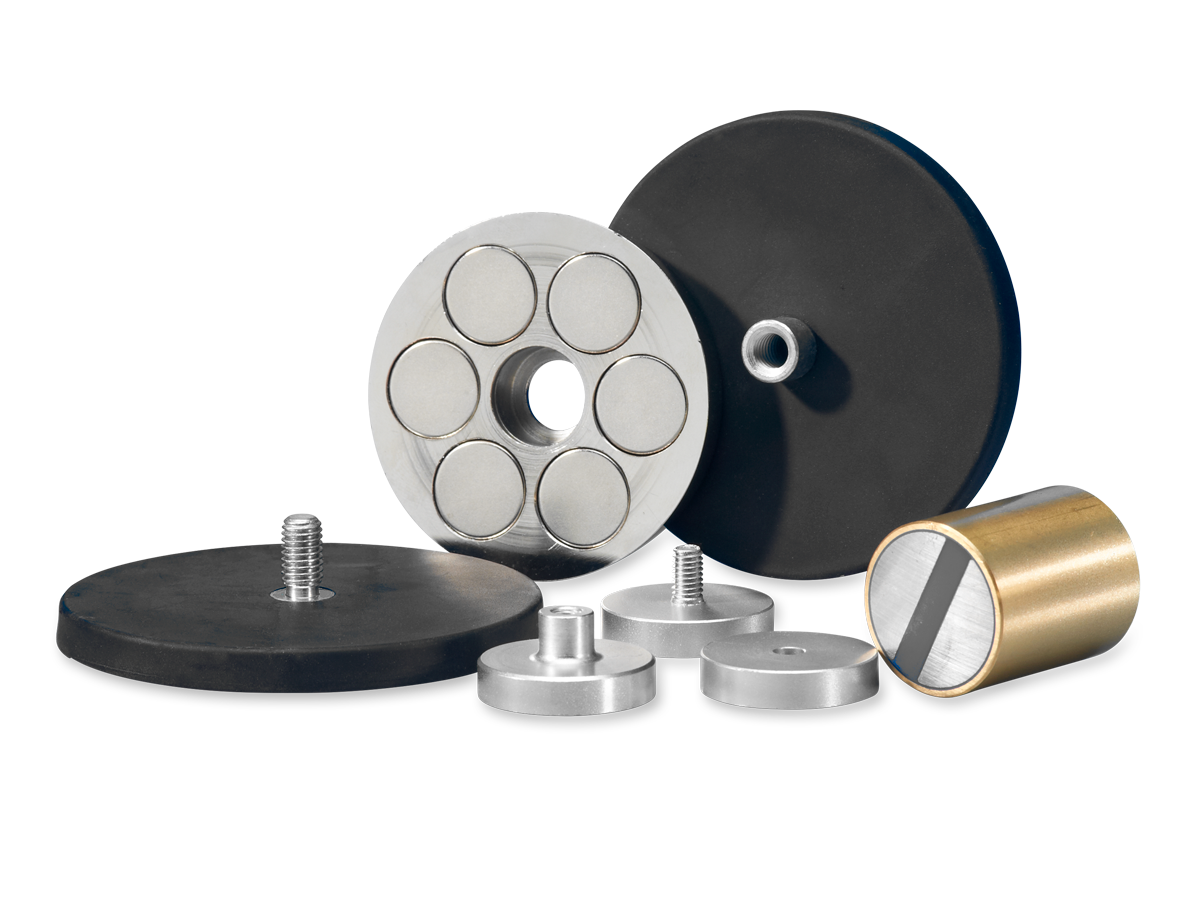

Neodymium pot magnets

Composition and construction of NdFeb pot magnets

These super-strong pot magnets are made of the alloy neodymium-iron-boron - (NdFeB) - which Goudsmit markets under the brand name Neoflux®. The shell provides magnetic shielding. Goudsmit supplies neodymium pot magnets with a brass or steel shell. The holding surface is covered with a protective coating to prevent corrosion.

The cylinder hole makes the magnet system screwable with a high torque.

Operating temperature and loss of magnetic strength

Neodymium pot magnets have a maximum operating temperature of up to 80 °C. When heated to this temperature, the magnet loses 15 to 20% of its magnetic force. This is not permanent; the force is restored when the magnet returns to the normal ambient temperature.

External magnetic fields may also cause loss of magnetic force. An air gap or non-magnetic materials located between the magnet and workpiece reduce the tensile force.

Ferrite pot magnets

Composition and construction of ferrite pot magnets

Good magnetic properties, affordably priced. Ferrite pot magnets, also referred to as ceramic pot magnets, are fitted with a steel pot that provides shielding of the magnetic field. Ferrite pot magnets require only a minimal installation height. This provides constructive advantages. Tighten with caution. Excessive tightening causes magnetic splinters or cracks in the magnet.

Ferrite pot magnets are corrosion-resistant and therefore do not require additional coating on the magnet surface.

Operating temperature and loss of magnetic strength

Ferrite pot magnets have an operating temperature of up to 200 °C. When heated to this temperature the magnet loses 30 to 40% of its magnetic force. This is not permanent; the force is restored when the magnet returns to the normal ambient temperature. The magnetic force of these pot magnets is lower than that of neodymium pot magnets.

External magnetic fields may also cause loss of magnetic force. An air gap or non-magnetic materials located between the magnet and workpiece reduce the tensile force.

AlNico pot magnets

Composition and construction of AlNiCo pot magnets

AlNiCo pot magnets are made of an alloy of aluminium, nickel and cobalt. They are encased in a steel pot, with a non-magnetizable material - brass or aluminium - in between.

AlNico pot magnets do not corrode and are very suitable for use at high temperatures. Tighten with caution. Excessive tightening causes magnetic splinters or cracks in the magnet.

Operating temperature and loss of magnetic strength

AlNico pot magnets have a very high operating temperature of up to 450 °C. When heated to this temperature, the magnet loses 30 to 40% of its magnetic force. This is not permanent; the force is restored when the pot magnet cools down to ambient temperature.

External magnetic fields may also cause loss of magnetic force. An air gap or non-magnetic materials located between the magnet and workpiece reduce the tensile force.

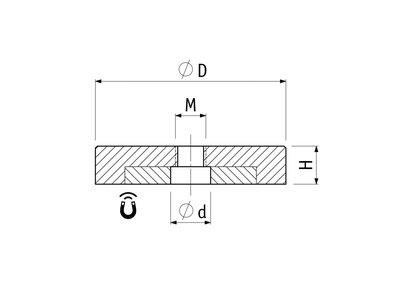

Compact magnet systems with a steel shell and thread for easy installation in places with low installation height. There is no force on the pot magnet for assembly. Due to the shell of these magnetic systems, the magnetic field strength increases and the pot magnets are more resistant to corrosion and chemicals.

Pot magnets have a single attracting surface. This precludes dispersion of the magnetic field.