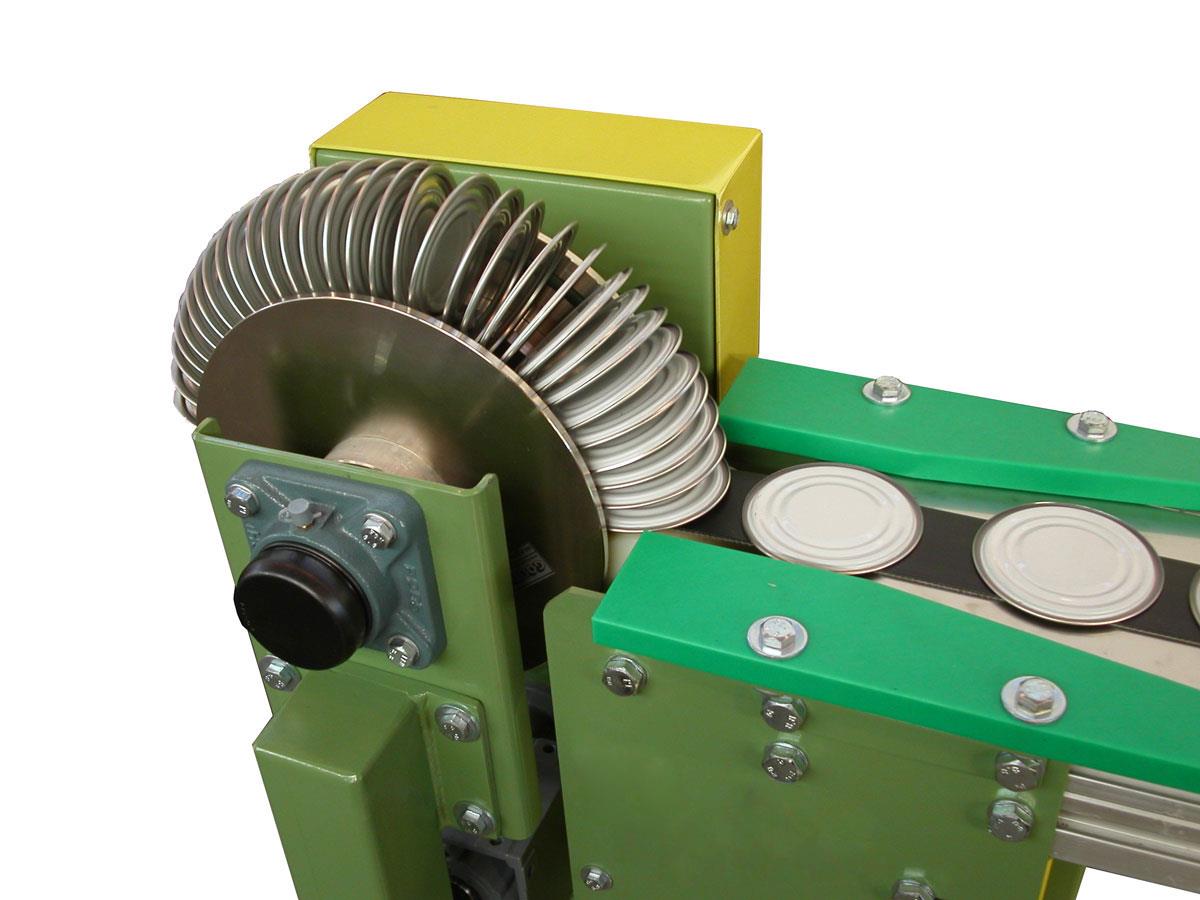

Magnetic lid stack rollers

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

Application of a magnetic lid stacker roller

Magnetic lid stacking rollers are suitable for lid diameters ranging from a minimum of 52 to a maximum of 180 mm.

The magnetic rollers are supplied in the form of two separate halves having a 25 mm shaft hole with keyway. Both halves are mounted on a (non-magnetic) stainless steel shaft. You can easily adjust the roller to the desired product diameter by adjusting the distance between the two halves.

Build your own transport system

With magnetic rollers and rail components, you can build your own magnetic transport system. This allows you to transport various products such as empty or full cans, lids, crown caps and so on. Selecting the different types and number of magnetic rollers can be a challenge. We are here to help: contact our technical experts, they will be happy to assist you.

Magnetic lid stack rollers stack and unstack lids, rings and discs of various diameters. Examples include feeding lids to filling/sealing machines in the canning industry or stacking rings in production lines.