Switchable sheet separators

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

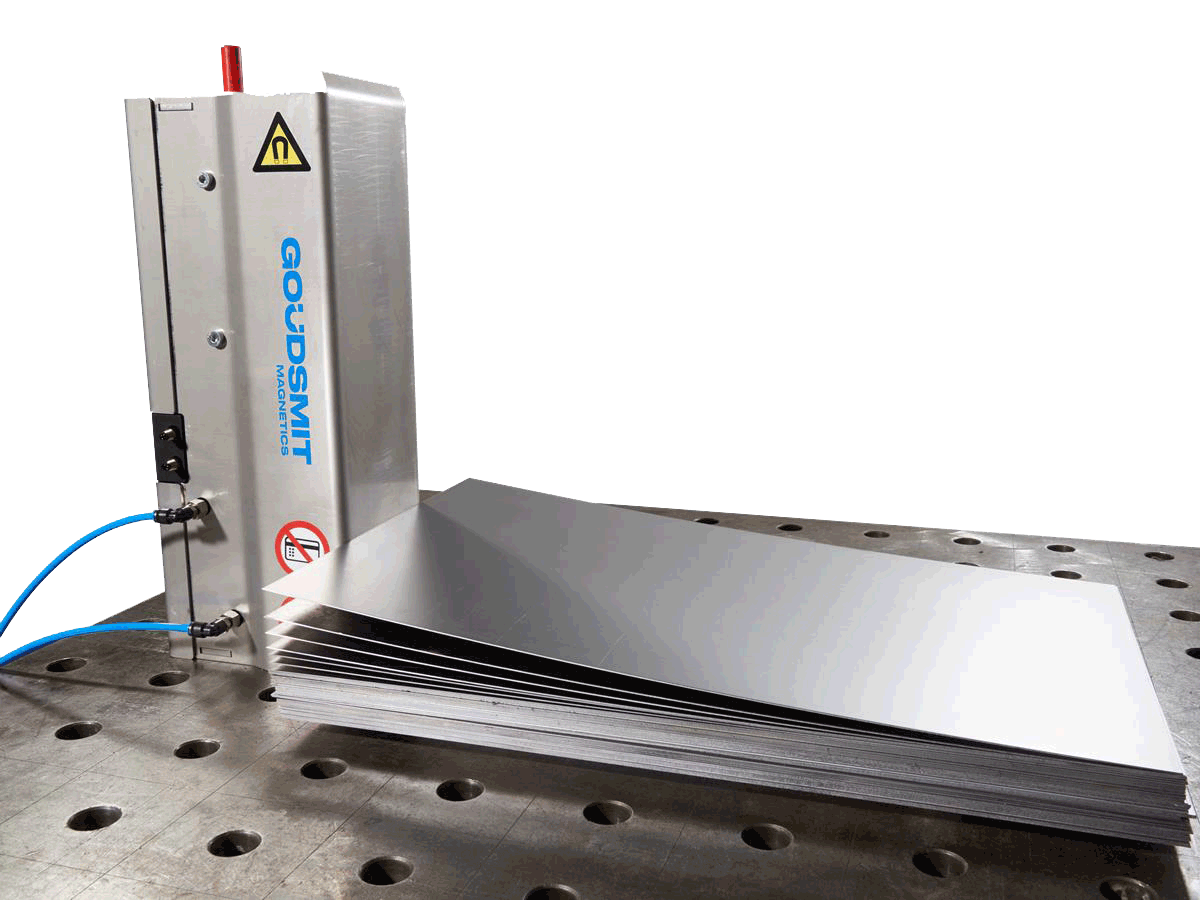

Application of switchable sheet separators

Sheet separators are used at the beginning of a production process, during the supply of stacks of sheet metal. But they are not only effective at the start of your process. At every step where stacking of sheet metal parts is required, sheet separators are an efficient and cost-effective means of increasing production speed.

Oil protects your sheet metal, but also causes the sheets to adhere together. This prevents rapid unstacking. In addition, picking up two sheets simultaneously can cause serious malfunctions or production errors. You can prevent these types of problems with robust and durable sheet separators. The magnetic field automatically pushes the sheets apart and separates them one by one from the stack below. When the next sheet is removed, the following one immediately rises.

Connection/commissioning

Pneumatically switchable sheet separators are easy to install. When they are connected to compressed air and positioned in the right place, they do their job flawlessly. The advantage of a pneumatic separating magnet is that you can fully automate your process. This is precisely this product’s function: to position sheet material simply and targeted or to present it for further processing.

You install manually switched sheet separators in the same positions as the pneumatically switched version. However, you do not have to connect these to compressed air, because the switching is done manually.

There are different types of magnetic sheet separators on the market, but Goudsmit fanner magnets stand out thanks to their construction quality. The basic design of your machine park should not be a daily concern for you. Our sheet separators do their work smoothly, without malfunctions and require very little maintenance.

Installation examples

Positioning sheet separators is a precise job. When the sheet separators are properly positioned and fixed, they are extremely reliable in separating your workpieces. With the right setup, the magnetic fields of sheet separators can complement each other and separate your products reliably. Incorrect positioning can result in unstable sheet metal or conflicting magnetic forces.

Be careful when positioning and fixing your sheet separators! It is a dangerous job and you always want to avoid being trapped between the two fanner magnets or metal in the surroundings. Do you have any questions about connecting or positioning your sheet separators? Please contact our experts. We will gladly help you.

Working principle

With the help of these advanced sheet separators, potential accidents are effectively prevented. The powerful magnetic field of sheet separators is not visible, which can cause employees to get their fingers stuck. The Goudsmit sheet separators are equipped with a powerful internal spring, which switches off the sheet separator under all circumstances in the event of an emergency stop or loss of air pressure. Even if a large stack of steel sheets is still attracted to the magnet.

Pneumatically switched sheet separators

Automatic sheet separators are easy to install. Once they have been measured and positioned correctly, they do their job flawlessly: positioning sheet material or preparing it for further processing. Thanks to the pneumatic switching and a patented fail-safe system, the sheet separator switches itself off when the air pressure fails.

Manually switched sheet separators

If you want to be flexible in the application, lightweight mobile sheet separators are a good option. You can easily move these yourself. By switching manually, you determine the magnetic force yourself, and no compressed air is required.

Switchable sheet separators are available in an automatic or manually switchable version. The automatically switchable ‘fail safe’ version has powerful neodymium magnets and can be switched on and off pneumatically using a new patented system. This safe separator automatically switches to the off position even in the event of a possible interruption of the compressed air. Also at full load of a maximum stack height or during maintenance.

If you want to be flexible in the application, lightweight mobile sheet separators are a good option. You can easily move them yourself and they do not require compressed air. By switching manually you also determine the magnetic force yourself.