Ferrite - overband magnets

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

Application of ferrite overbelt magnetic separators

An overbelt magnet is suitable for removal or separation of high volumes of iron or steel and hangs above a flat- or trough-shaped conveyor. This type of magnet is self-cleaning and continuously separates (ferromagnetic) Fe parts from material streams. The iron removal efficiency of overband magnets ranges from 70 to 90%. This depends on magnet design, product flow and placement. Automatic self-cleaning overband magnetic separators are suitable for both the recovery (recycling) of ferrous parts and the removal/elimination of impurities (iron contaminants).

These magnets are mainly suitable for coarser fractions with pieces larger than 10 mm. Thanks to the robust, reliable technology, these magnets have applications in many industries. Putting a permanent overbelt magnet in service requires nothing more than four suspension points, sufficient space and power to drive the conveyor belt.

Operation of overbelt magnets

Conveyor belt speed:

to remove ferrous or iron parts from a material flow, they must remain in a magnetic field for between approximately 0.3 and 0.5 seconds, where they are magnetized. To achieve maximum separation, it is important to optimally match the size of the magnet block (main pole) and the belt speed. This means that with a narrow overband magnet the conveyor belt beneath it must run at lower capacity (m/s) than with a wider magnet at the same suspension height.

The following formula provides an indication of the maximum conveyor belt speed:

- Maximum conveyor belt speed (b) = block magnet width (a) / 0.3 (sec.)

- Recommended conveyor belt speed (b) = block magnet width (a) / 0.5 (sec.)

.jpg)

Placement of overbelt magnets

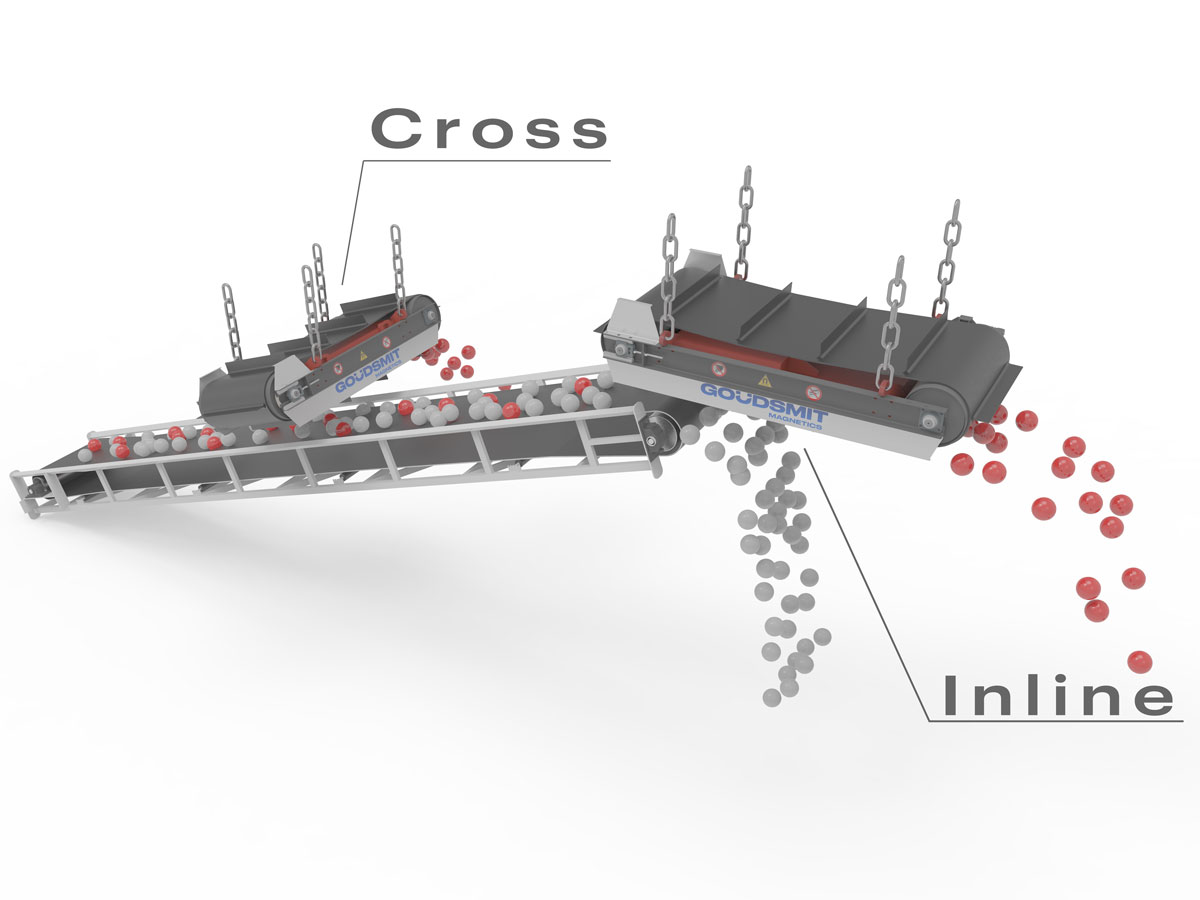

The distance between a magnet and the conveyor belt must be as small as possible. The magnetic force decreases exponentially with increasing distance. There is, however, a minimum distance required so the rubber cleats safely remove all the ferrous parts from the material flow. There are two methods for use/placement of overband magnets: transverse and in-line. Goudsmit has a specific, optimum magnet configuration for both mounting options.

Transverse ('Cross') - cross belt magnetic separator

In practice, transverse placement is most common, because it is easier to install in an existing line. An additional advantage is a ferrous discharge to the side, which from the logistical perspective is easier to process.

‘In-line’

If you have the option to place your overband magnet in line with the conveyor belt, this is always preferred. The advantage of this is that the transported material ‘breaks open’ at the end of the belt (head roller) and is therefore suspended in mid-air for several milliseconds. As a result, the magnet can easily pull the ferrous metal out of the product flow.

Non magnetic zone

When positioning the magnet, the construction below the magnet such as the frame, bearing rollers and end rollers must be made of non-magnetic material. This is because steel parts will become magnetized, which will adversely affect the separation performance of the overband magnet. For more information about this: see non-magnetic zone.

.png)

Ferrite overband magnets deliver the best balance of price and performance, offering a cost-effective and reliable solution for ferrous separation. The advanced Tri-pole magnetic system, featuring an auxiliary pole, ensures efficient extraction and a smooth discharge process. Designed with low-maintenance construction and protective covers, these magnets require minimal cleaning and experience less wear, enhancing their durability. Available in both cross- and inline configurations to suit various application needs.