Neodymium magnets NdFeB - custom

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

The right magnet for your application

Your product with magnets is unique and has its own set of requirements. Goudsmit has a complete range of magnets, so that we always supply the right model.

Step-by-step plan to find the right magnet:

- Select the type of magnet you are looking for

- Request your non-binding quote

- Enter additional information in the comments field

- Send your request for a quote

- Our advisers will process your request and contact you.

Alternatively, contact us directly using our contact form.

NdFeB magnet grades

Neodymium magnets are available in different grades, from N35 to N55SH. Each with unique magnetic properties, such as Br energy product, HcJ resistance to demagnetization, and temperature resistance.

Click on the above magnets or download the free specification sheet of the desired magnet grade.

Our technical specialists are ready to help you choose the right magnet for your specific application. Please feel free to contact us for advice or more information about our products and services.

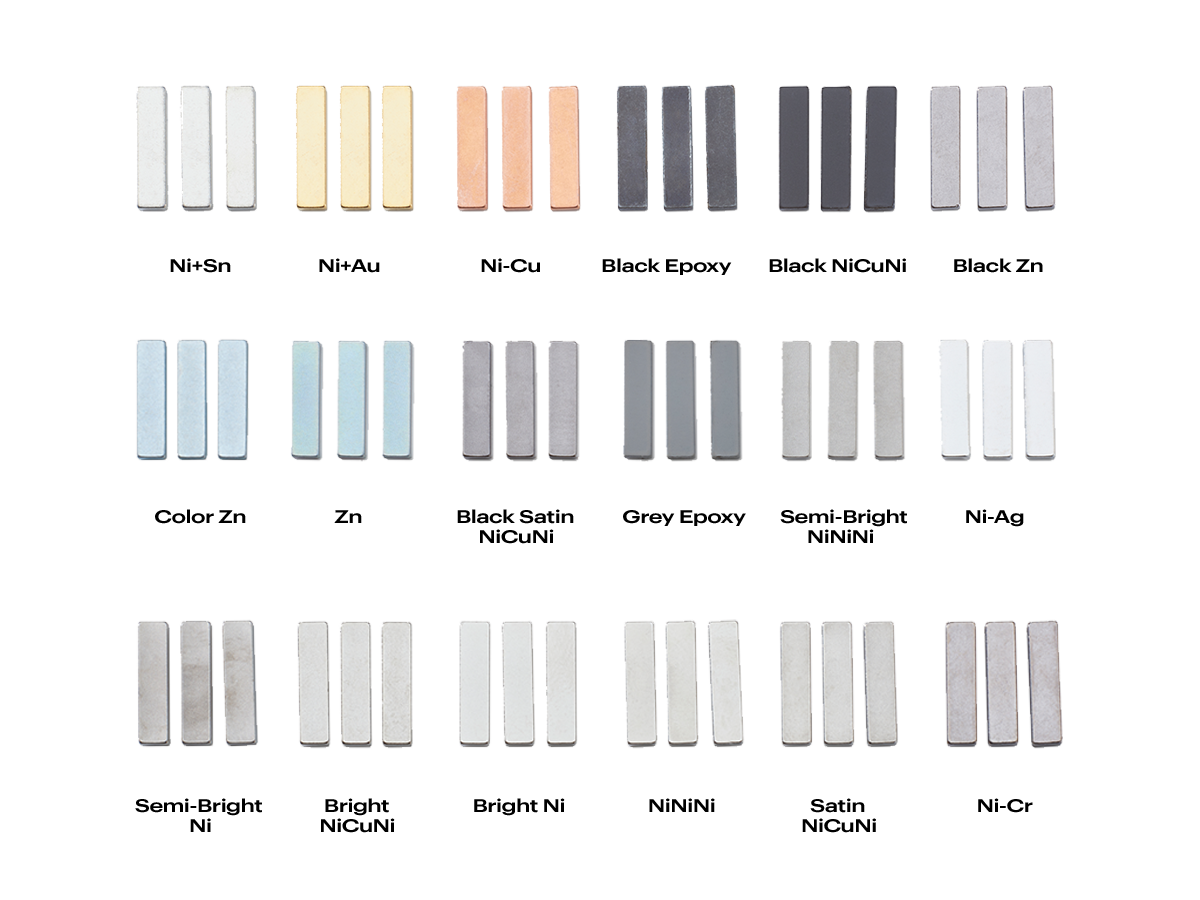

The right coating for protection and manufacturability

Although neodymium is magnetically the strongest alloy, it also has less favorable properties. Sensitivity to corrosion, low temperature resistance, poor adhesive properties, and mechanical brittleness partly determine whether this type of magnet can be used in your product. A suitable magnetic coating can offer a solution for this. Download our free magnet coating selection table.

We have various options for coating NdFeB magnets, such as:

- Ni-Cu-Ni (standard): the most commonly used coating to protect against corrosion in normal applications.

- Ni-Cu-Epoxy: susceptible to scratching, but has very good adhesive properties with high breakaway force.

- HDPE: thicker coating that protects against UV radiation.

- Parylene: ultra-thin, pinhole-free polymer coating with superior abrasion resistance.

- Ni-Au: thin 24 carat gold layer on top of nickel coating. Used for medical applications.

- Plastic: super durable and highly corrosion resistant. It protects magnets from breaking on impact and prevents corrosion by creating a watertight barrier between the magnet and moisture.

- And many more.

It can be difficult to select the best coating due to the many factors that affect a magnet’s durability and performance. You can always contact our magnet experts with questions or for help choosing the right coating for your project.

More than just a magnet

The possibilities with magnet technology are endless, which is why it can quickly become confusing. Goudsmit has more than 60 years of experience in the world of magnetism and is happy to help you with advice and a range of services:

- FEM simulation & magnet calculations: gain quick insight into the operation of your design.

- Prototyping & samples: tangible magnet technology based on your requirements.

- Engineering: development of magnet assemblies and components.

- Quality control: critical properties tested and validated in our own measurement lab.

- Certification: ISO9001.

- Stock management service: delivery of your magnets on demand through our modern warehouse.

You can choose whatever form of support you want. This guarantees you the right magnet for your specific application.

Neodymium-iron-boron (NdFeB) magnets offer the highest energy product of all magnet materials. They are available in a wide range of shapes, sizes, direction of magnetization, coatings and grades. You can find NdFeB magnets in many applications, such as electric motors, sensors, switches and loudspeakers.

Goudsmit offers a wide range of services with regards to the design and selection of the appropriate magnet for your specific application. For instance, we apply magnet calculations and FEM simulations to quickly identify the best magnet for your product. In addition, we have all the necessary processes in place to supply the automotive and aerospace industries and we follow the IATF16949 guidelines.