Magnetic palletizers

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

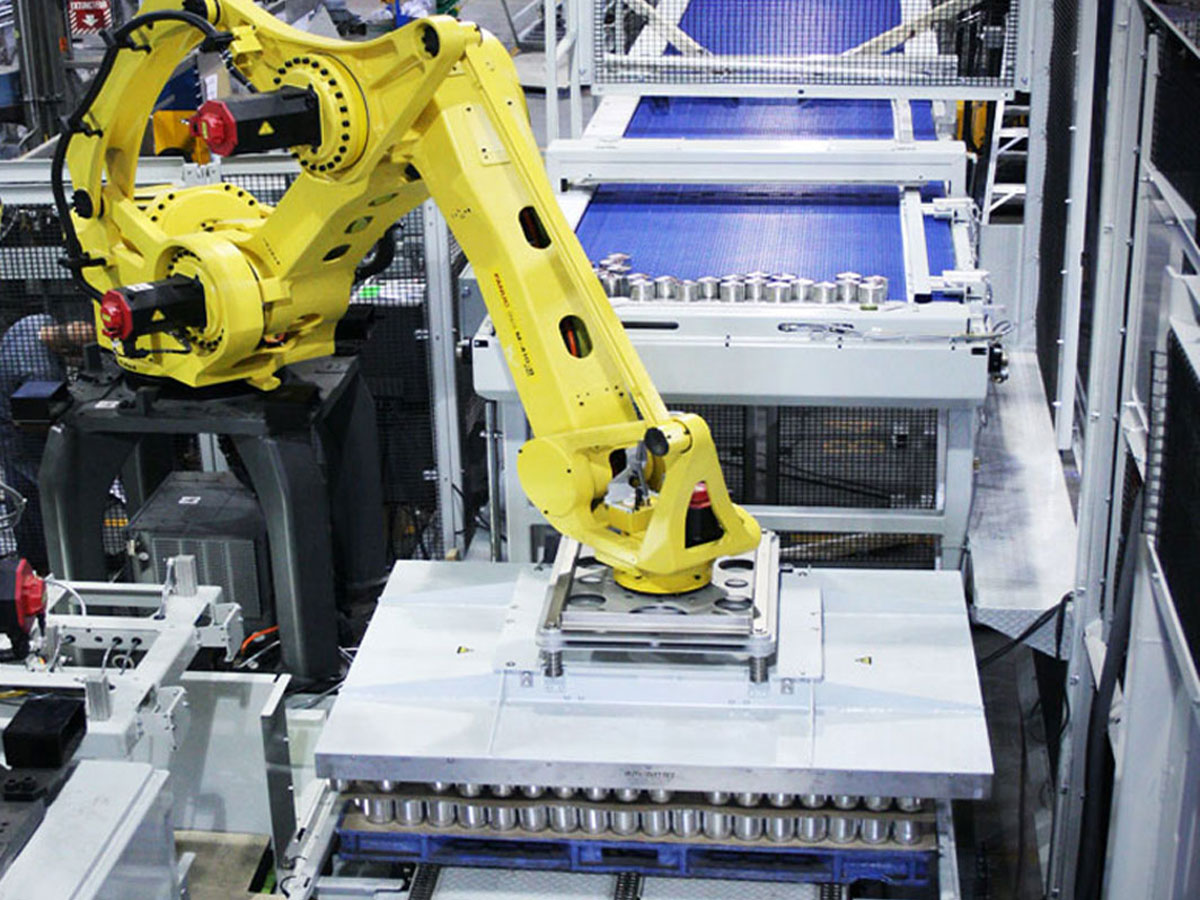

Application of palletising magnets

Goudsmit magnetic palletizers use permanent magnetic force to lift and hold steel products in one go. They do this without a power supply. Palletization magnets hold a layer of products for as long as needed.

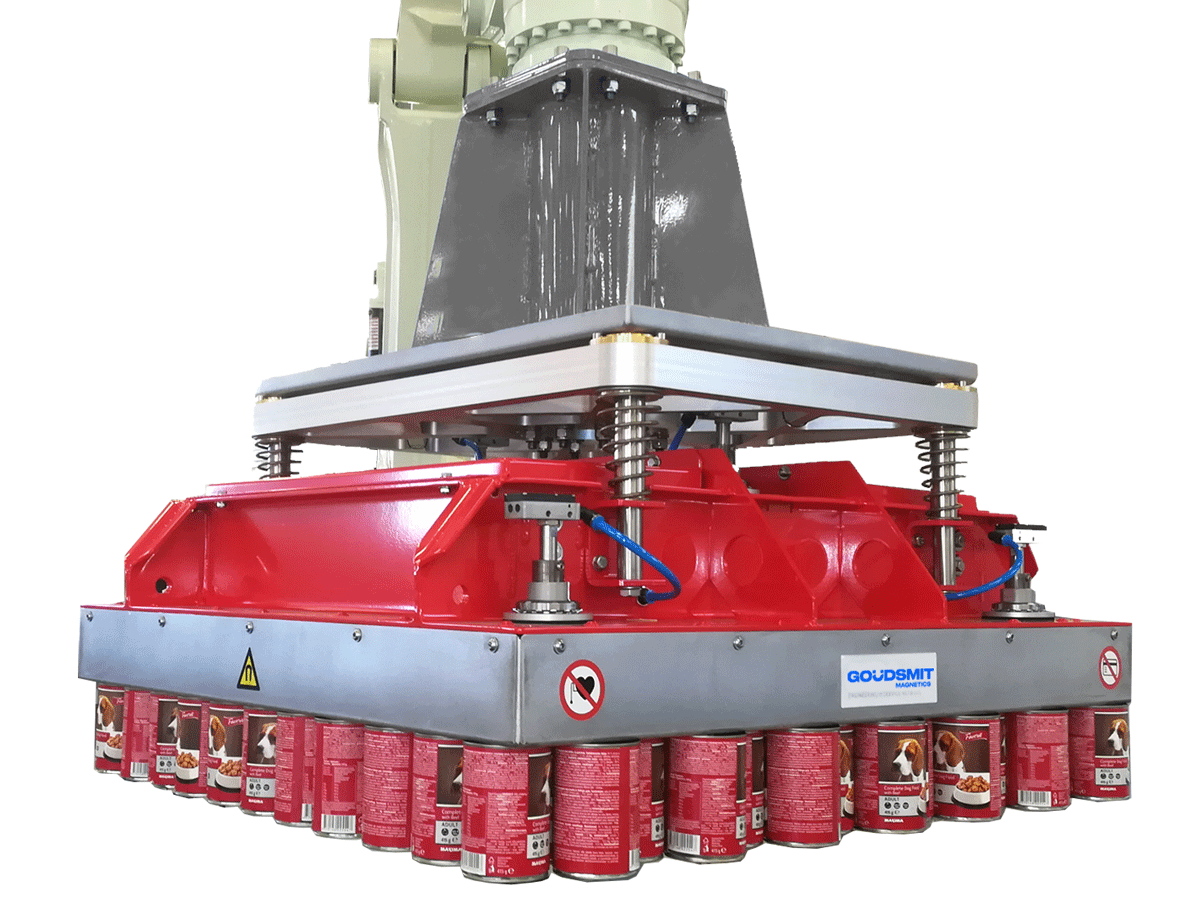

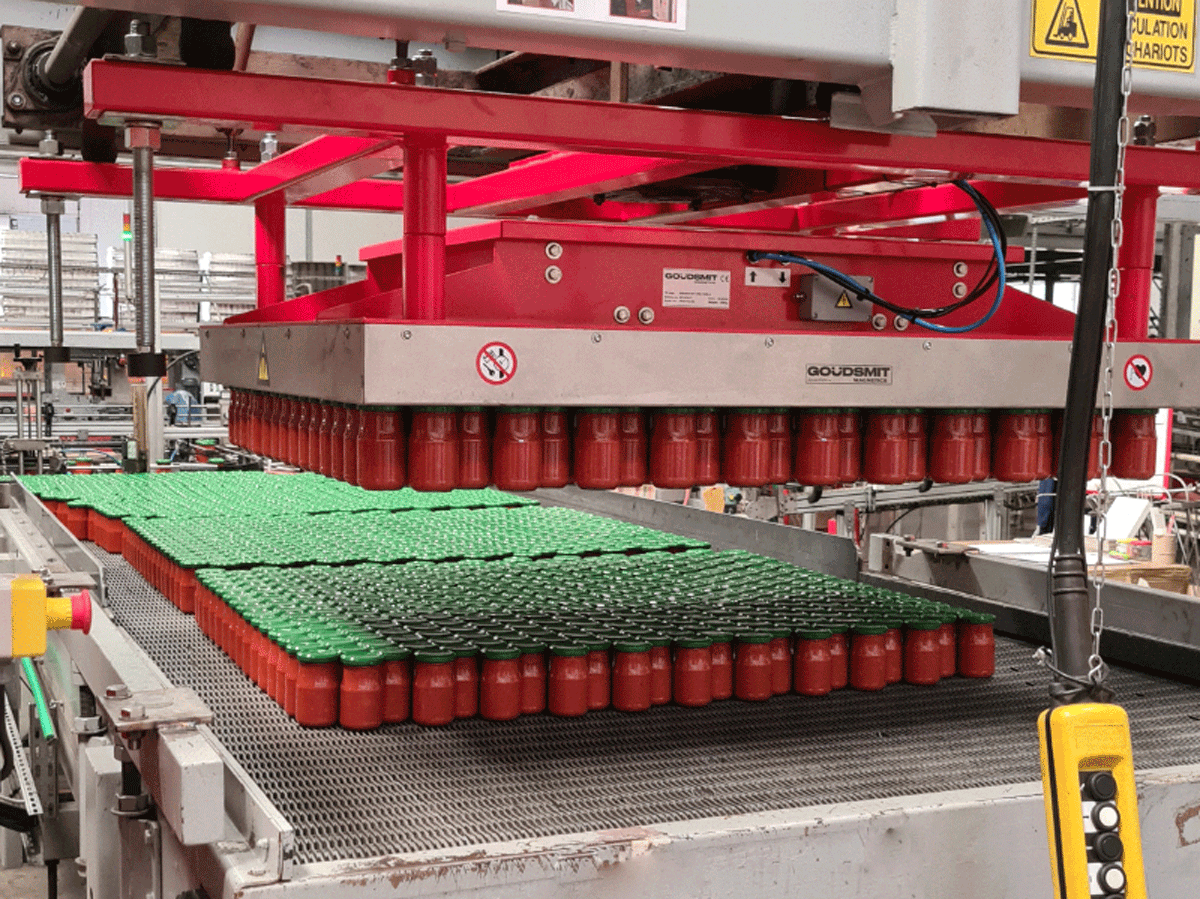

Design of palletising magnets

The unique parallel mechanism of the palletization magnet guarantees a trouble-free production process, even with non-uniform loads. For example, when picking up a half layer with products. The special Goudsmit design has a long service life, requires little maintenance and consumes little air.

Operation per magnet system

With neodymium - Neoflux® - medium pole magnet system.

For palletizing large filled tins.

Product dimensions:

- tins: min. Ø65 mm (up to 0.6 kg) - max. Ø230 mm (up to 5 kg).

With neodymium - Neoflux® - fine pole magnet system.

For palletizing/depalletizing extra-large filled tins and filled jars with screw lids.

Product dimensions:

- screw lids: Ø34 mm (up to 0.45 kg)

- screw lids: Ø42 mm (up to 0.85 kg)

- screw lids: Ø56 mm (up to 1.1 kg)

- screw lids: Ø82 mm (up to 2.2 kg)

- screw lids: Ø110 mm (up to 4.0 kg)

With palletization magnets, you pack tins, aerosols, cans and glass jars with steel lids in one go. The magnet holds a layer of products without an energy supply. They are suitable for attachment to a robot arm or gantry crane (palletizing machines) and help with packing and unpacking in automated processes.