Permanent bullet magnets

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

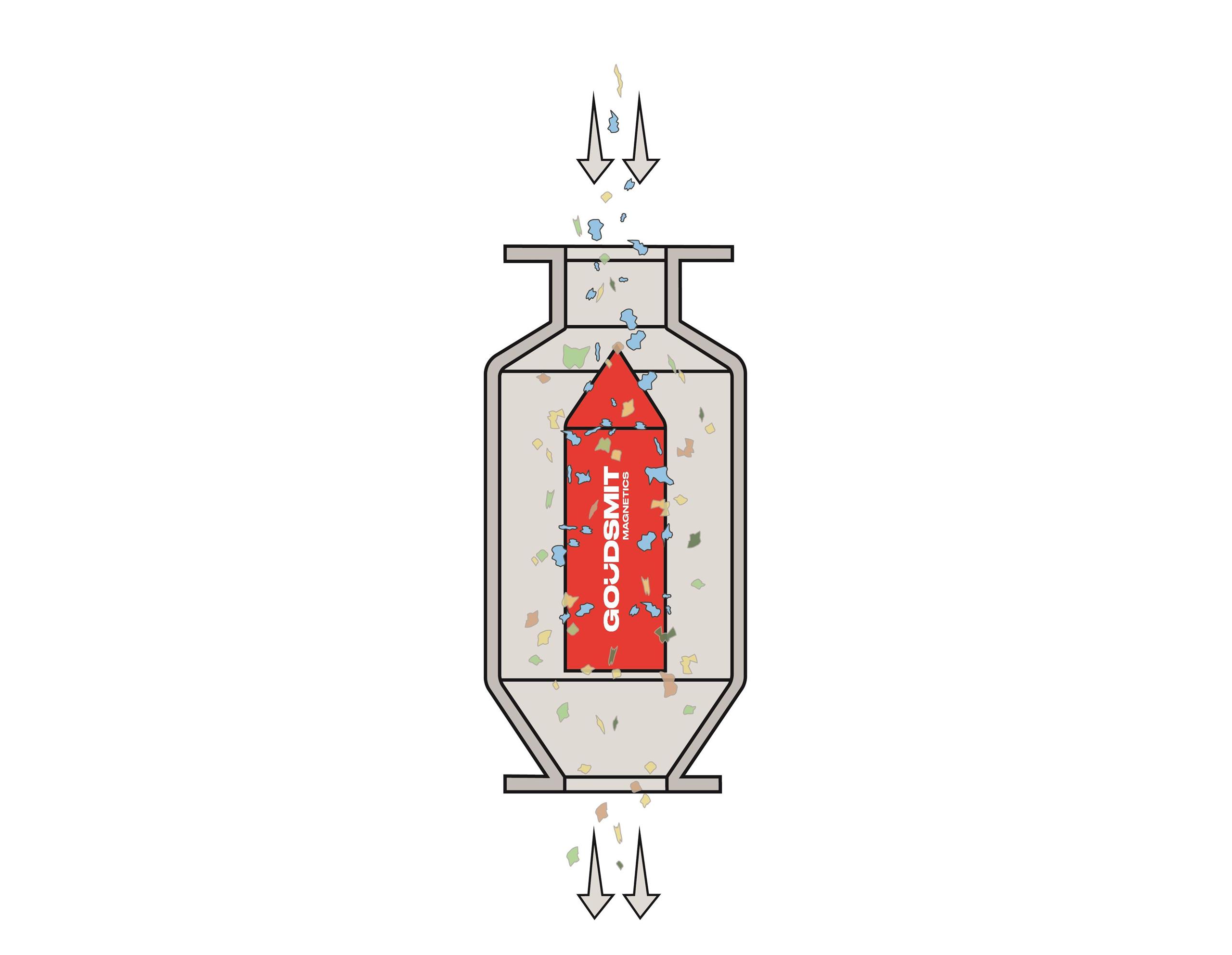

Application: filtering iron contamination out of high capacity coarse product streams

For filtering ferrous contaminants – such as iron and steel – out of granulates, fibres and coarser materials in high capacity non-pressurized pipelines. Bullet magnets are used in the bulk, animal feed, plastics, ceramics and recycling industries, among others.

Construction & materials data

Permanent bullet/pipe magnets are built with a large, cylindrical permanent magnet core, with a powerful, deeply penetrating magnetic field. The magnet core filters the metal particles out of the product flow and retains them on three magnetic poles until they are cleaned.

- 1 bullet-shaped magnet with 60° top cone

- Robust steel / stainless steel housing

- Incl./excl. welded tapered in-/outlet

- Flanges acc. DIN24154, or Jacob connections (only for tapered in-/outlet types)

- Finish: painted

- Dust explosion-proof Ex II 1/2D

Available accessories & options

- Housing made of AISI316 stainless steel instead of 304

- Door sensor (open/closed safety)

- Upside-down versions for upwards ventilated product flows

- Magnet iron saturation signaller ‘Met-alert Watch dog’

- Kobaflex PU protective coating

Working principle: filtering & discharging of ferrous contaminants

How does the magnetic filtering work?

Because the magnetic core is located in the middle of the product stream, the bullet magnet has a very high separation yield. The round shape of the housing and the magnetic core (with a 60° top cone) ensures continuous flow and good distribution of the product stream.

The product then passes three powerful magnetic fields, where guide strips redirect any product near the outer walls back toward the magnetic core. The magnets attract passing ferrous particles. The captured particles stick to 1 of the 3 magnet poles, while the purified product flows further.

How does the cleaning / iron discharging work?

You have to remove the captured ferrous particles manually. After having stopped the product flow, you can open the door. Then turn the magnet around its own axis, while wiping the magnet clean.

Cleaning / iron discharging sequence

- Stop the product flow.

- Loosen the fastener clamps.

- Put on sturdy work gloves.

- Open the door as far as possible.

- Wipe clean the magnet core while turning it around its axle.

Catch the removed ferrous particles and dicharge them. - Re-tighten the fastener clamps.

- Restart the product flow.

Permanent bullet magnets have a powerful bullet-shaped ferrite magnet core. They are suitable for filtering medium to large ferrous contaminants from high capacity coarse free-fall bulk flows. Often used in eg. the bulk, animal feed, plastics, ceramics and recycling industries. Permanent bullet magnets have a lower installation height compared to electro bullet magnets. Yet, you have to clean them manually, where this is done automatically with the electro bullet magnets.