Custom magnet assemblies

The demand for high-quality magnets for complex components and applications is growing continuously. Goudsmit Magnetics has the know-how of high-tech custom magnet assemblies and magnet technology. FEM calculations, 3D simulations, technical design, prototype construction and high-tech production methods, analyses and testing.

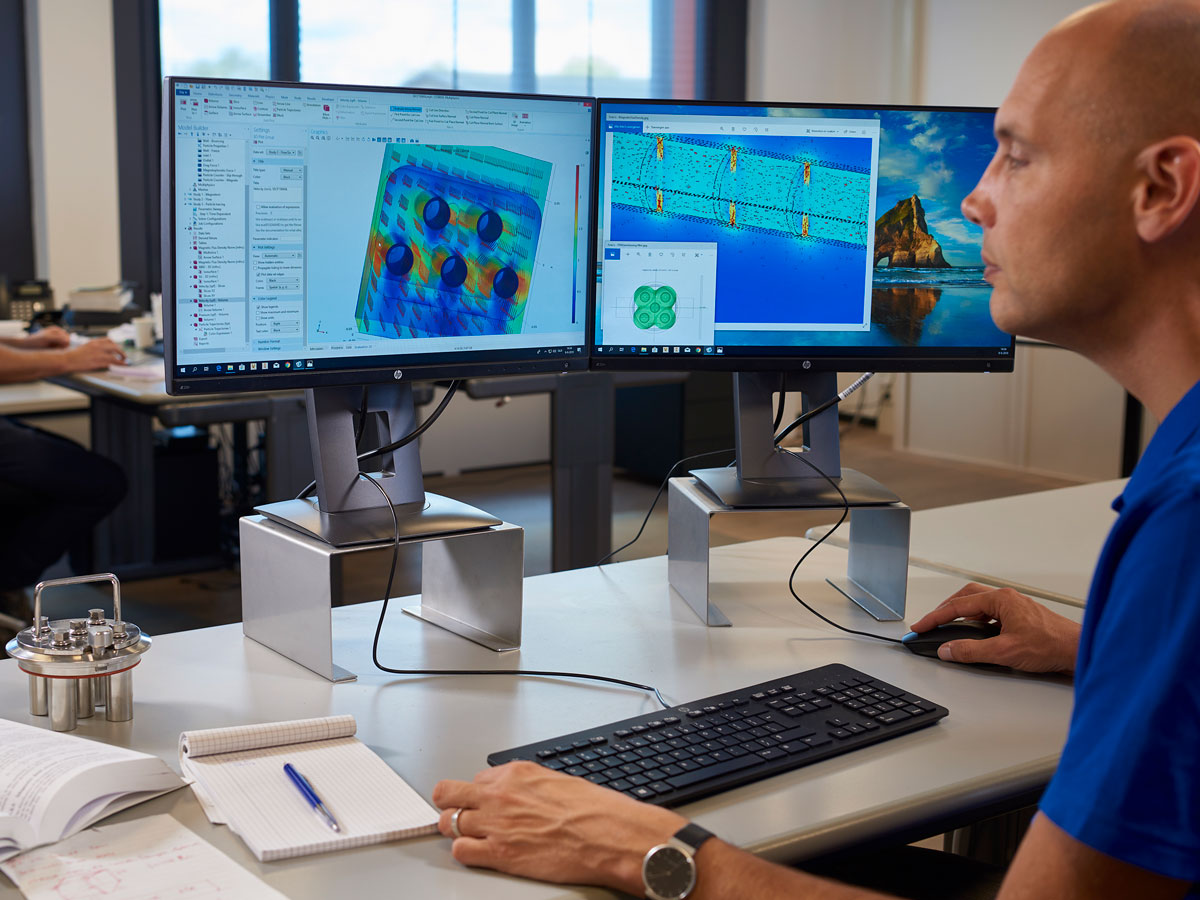

Calculation & simulation

With state-of-the-art FEM software, our engineers develop the perfect magnet for a new or existing product faster and better. This gives you certainty that your magnet meets all specifications.

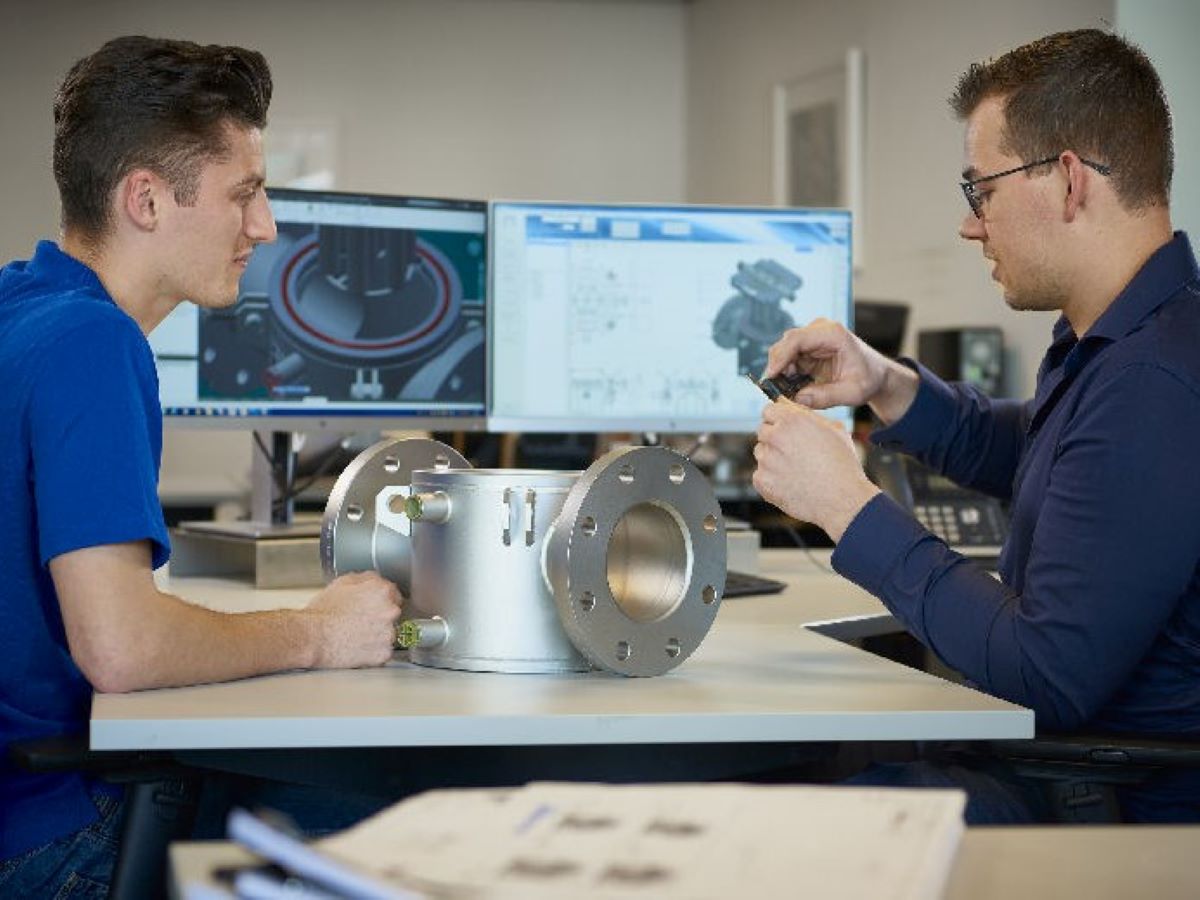

Engineering

The function of the magnet determines which specific properties are required. Goudsmit's engineers ensure optimum design.

Production magnet assemblies

With modern production and assembly facilities, we build, test and measure your magnet assembly: from prototype to series.

Magnet prototypes

Using various production methods, material choices and magnetic alloys, you get a customised prototype. A magnet with the right magnetic performance that contributes to cost savings and a longer delivery time before series production starts.

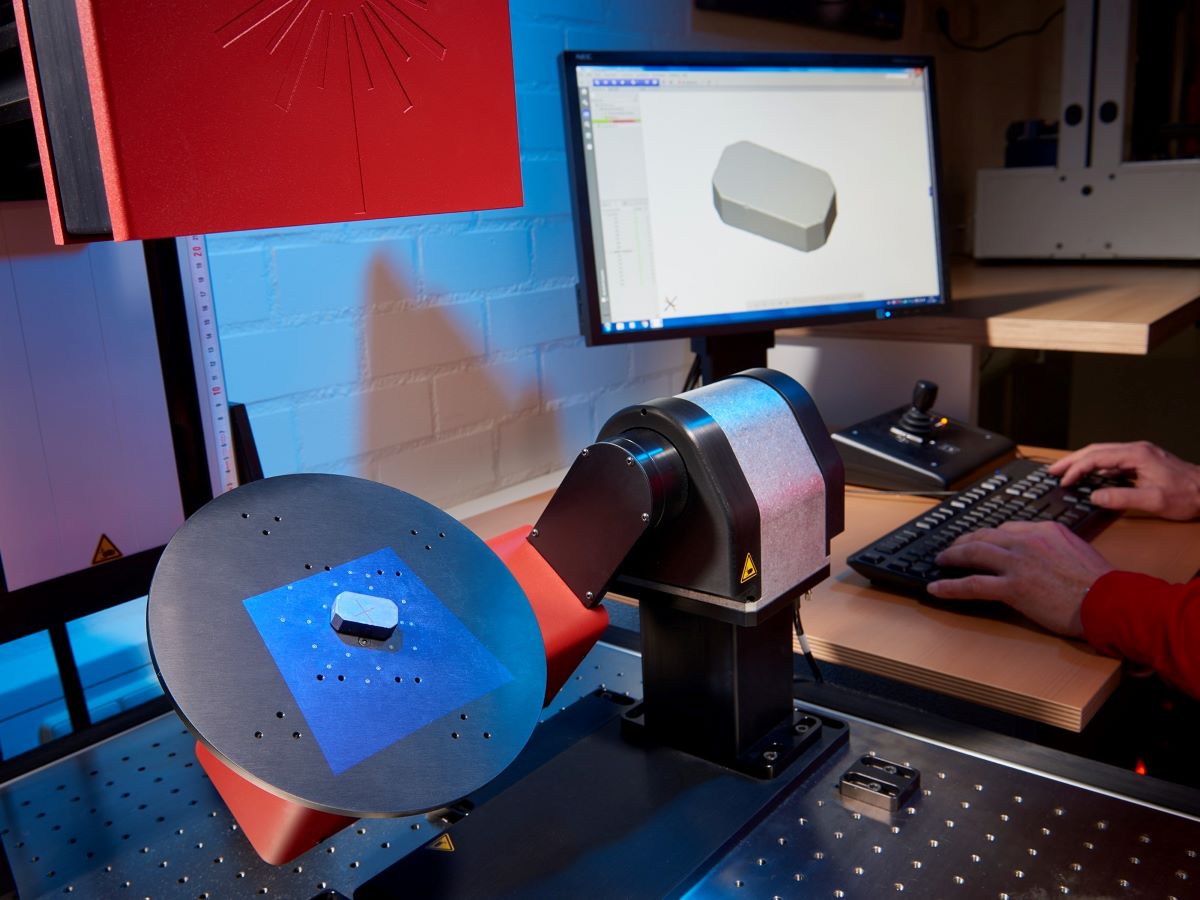

Magnet validation, measuring, inspection

Geometry, polarisation and magnetic properties must meet your requirements. Our QA/QC engineers work with state-of-the-art techniques and software.

High quality magnet assemblies

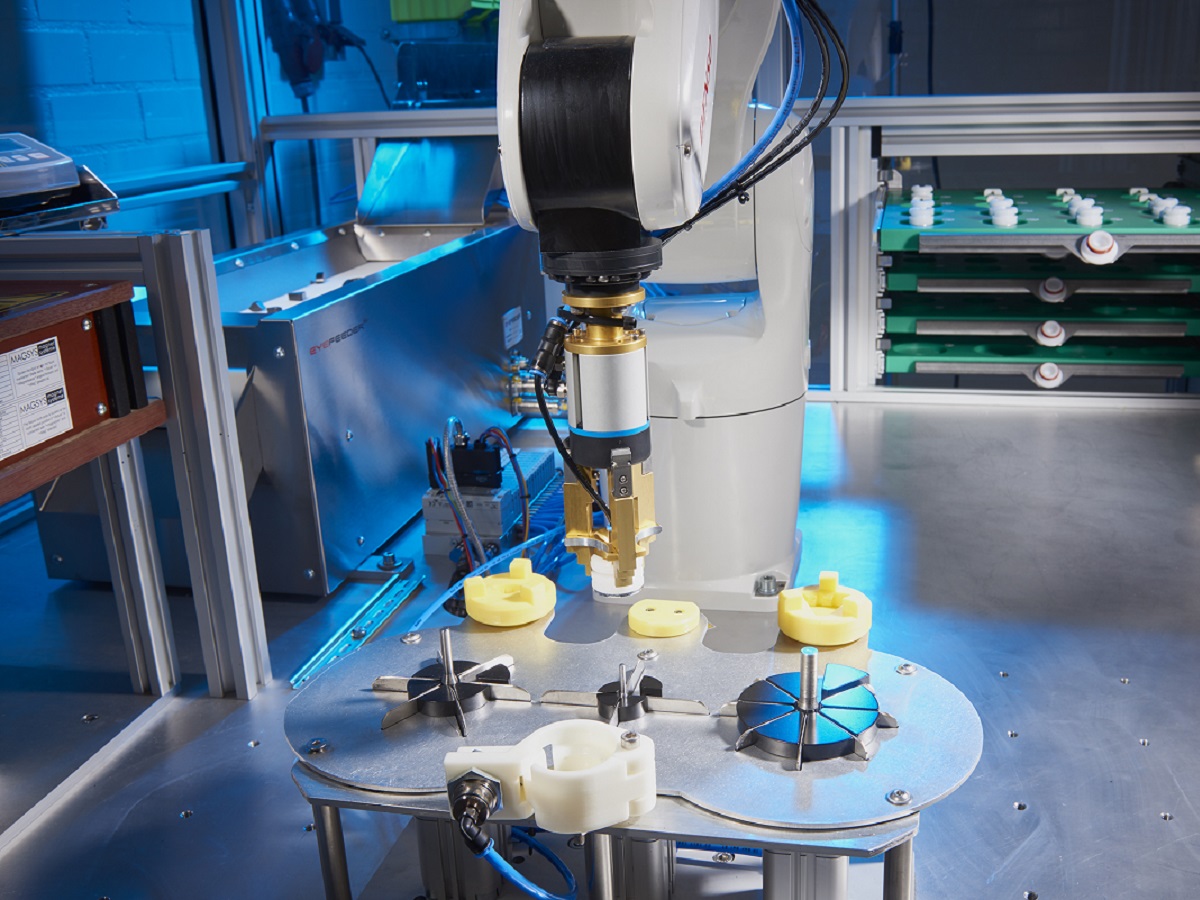

Goudsmit Magnetics' modern production and assembly facilities have everything necessary for building, testing and measuring magnet assemblies, prototypes and series. We use a robot to produce magnets with consistent quality and traceability. This is mandatory for supply to the aerospace industry.

Automated production of magnetic components

RobofrOK stands for First Run OK and is the name of our specially designed production area, where we produce magnet systems and magnetic components that are entirely free of production-related defects. RobofrOK provides a semi-automated production process at a constant temperature, with optimally organized processes and flexible production lines. We guarantee fast delivery, full traceability, transparency and high quality. We create prototypes for customers and changes for the robot using a 3D printer. This ensures rapid turnaround times.

Is a magnet assembly suitable for your application?

Demand for complex components and products with integrated magnets is growing steadily, and this requires expertise in the field of magnet technology. Our team of experienced engineers investigates which magnet assembly delivers the right magnetic performance for you while contributing to cost savings and longer life. Through various production methods, material choices and magnetic alloys, we produce custom-made magnet assemblies.

Fabrication methods

Goudsmit Magnetics has expertise in the following fabrication methods for production of magnet assemblies:

- Ultrasonic welding of magnets

- Gluing magnets

- Overmoulding magnets

- Mechanical assembling

You can read more about magnet assemblies and the solutions they offer for many magnetic applications below.

What advantages do magnet assemblies offer?

A magnet assembly consists of a combination of magnets and non-magnetic materials that often form a stronger magnetic field together. The non-magnetic materials protect the magnets from damage. They also contribute to a mechanically stronger magnet system. Magnet assemblies with special fastening capabilities for holding or securing objects are also possible.

- Stronger magnetic field

A magnet assembly is not only mechanically stronger but often has a greater magnetic force compared to magnets. This is because, in addition to the magnet, the conductive elements are part of the magnetic circuit. This magnetic force is strongest when the magnet assembly is in direct contact with the workpiece. Even the smallest opening, in the form of an air gap, coating or dirt, will significantly affect the magnetic field. - Magnet with housing is mechanically stronger

Magnetic alloys are usually weak. Due to constant mechanical load, particles break off. This causes the magnet to lose volume. Consequently, the magnetic field weakens. A magnet can be manufactured with a protective housing or pot that prevents this from happening. A fully enclosed magnetic system may also be necessary due to environmental requirements. Goudsmit Magnetics has various assembly options to fit a magnet with a plastic, ferrous metal or non-ferrous metal housing. You can read more about overmoulding, ultrasonic welding and injection moulding of magnets here. - Magnets can be fitted with a rubber coating to provide protection against damage.

A rubber coated magnet prevents scratches on the surface. This type of magnet also has a higher shear force, which makes them ideal for vertical applications such as hanging whiteboards on steel walls. Moreover, a housing protects the magnet system from moisture and dirt. A rubberized magnet can be used in damp spaces and outdoors. You will find our range of rubberized wall magnets here. - Magnetic fastening of objects

With press fits and screws, we produce magnet assemblies with a threaded hole or threaded stud, suitable for mounting. This allows you to magnetically fasten objects. These magnetic components are easy to use and save you time and money. Gluing, screwing and unnecessary drilling of holes are things of the past. We have a standard range and also deliver custom-made magnets.