Cascade magnets

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

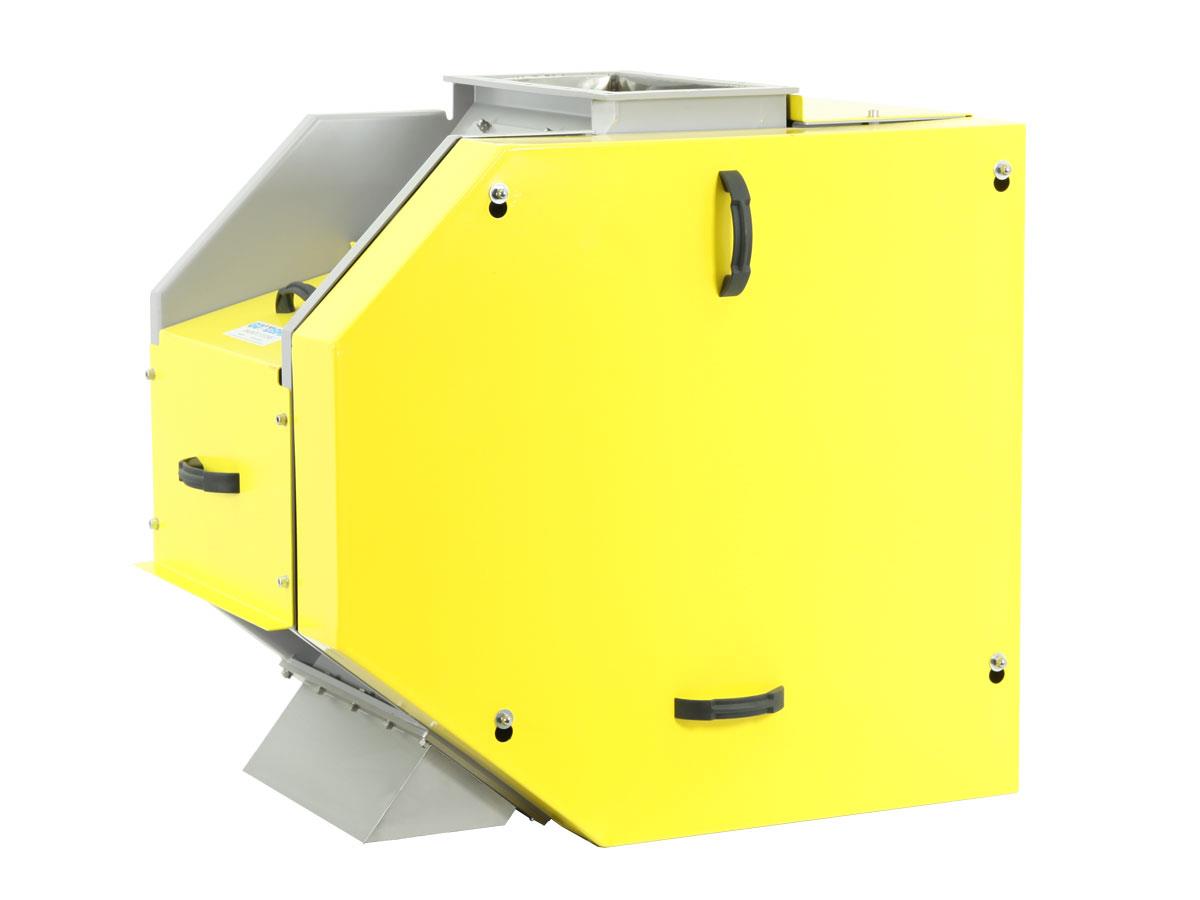

Application: for coarse, high capacity material flows

Cascade magnets filter ferrous contaminants - such as iron and steel - out of granulates, fibres and coarser product flows in high capacity free-fall pipelines. They are often used in the bulk, animal feed, plastics, ceramic and recycling industries, among others.

Construction & materials data

The robust housing has 3 cascade stages by default. Each stage has a plate magnet against the outside of the housing. These plate magnets have a powerful and deep magnetic field, that extracts the ferrous particles out of the product flow. They retain those ferrous particles until they are cleaned. The last magnet is an extra strong neodymium version to obtain an even better separation efficiency. The magnets are clamped against the housing by pneumatic cylinders, also when air pressure is lost.

- Magnet quality: ferrite / neodymium

- Materials - in contact with product: stainless steel

- Finishing: painted

- ATEX marking: Ex II 1/2

- Dust/water protection class: IP54

- Solenoid valve electric supply: 24 V DC

- Pneumatic supply: max. 6 bar

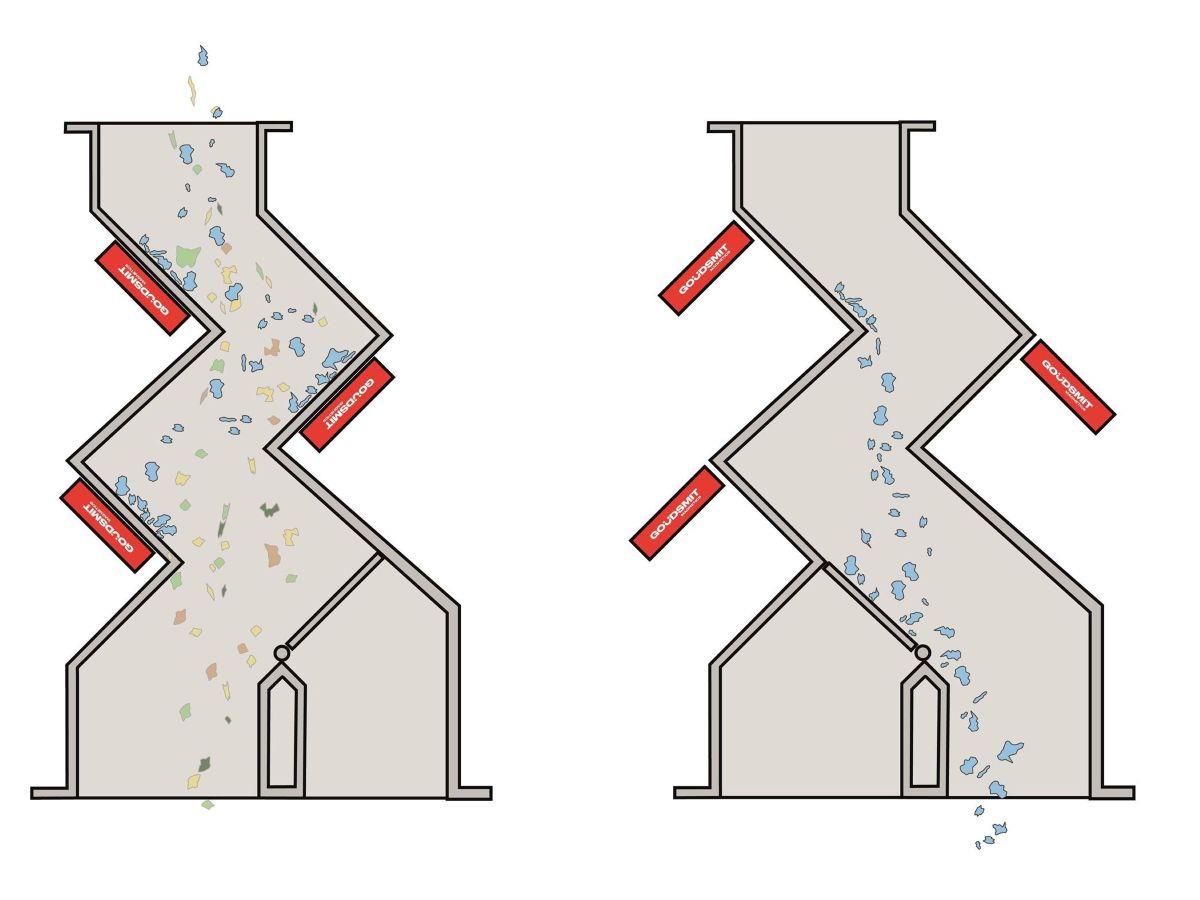

Working principle: filtering & discharging of ferrous contaminants

How does the magnetic filtering work?

The plate magnets have a powerful and deep magnetic field, with which they pull the ferrous particles from the product flow. The ferrous parts are clamped against the magnet and held there until they are cleaned.

How does the cleaning / iron discharging work?

With the cascade magnets, you must stop the product flow in order to clean the magnets from filtered ferrous particles.

Cleaning / iron discharging sequence

- Stop the product flow.

- Send the signal to the controller to start a cleaning cycle.

- After a start signal is sent the cleaning process is performed completely automatically, via a pneumatic sequence circuit:

- Iron discharge valve opens to its iron discharge position.

- Magnets move away from the housing – the iron falls off and is discharged via the iron discharge chute.

- Magnets are pulled back against the housing.

- Iron discharge valve closes to its production position.

- Restart the product flow.

The robust cascade shaped housing forces the product to closely pass 3 plate magnets. Because these are placed outside the product channel, the pipe channel is unobstructed. In this way, high capacities can be processed, and a high separation efficiency is achieved. Cascade magnets - also called magnetic humps or hump magnets - filter ferrous contaminants from 0.5 to 50 mm from free falling coarse product flows, and are cleaned automatically.

Application examples: bulk, animal feed, plastics, ceramics and recycling industries.