MagVacu® combi grippers

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

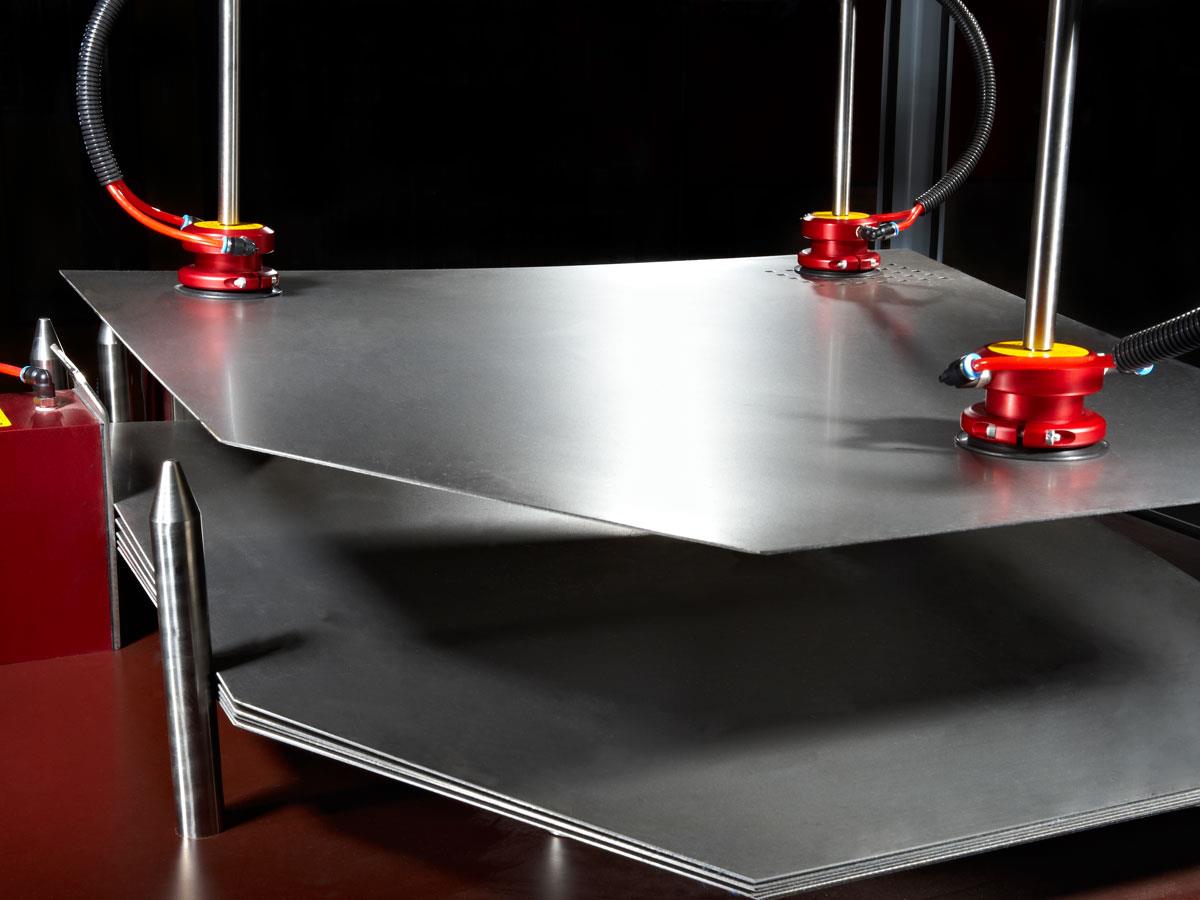

Application of the MagVacu® gripper

MagVacu combi grippers are an ideal solution when you work with steel sheets as well as stainless steel or aluminium sheet metal. The flexibility of this gripper is ideal in laser cutter, automotive assembly line and sheet metal industry environments. For example, you can easily handle perforated, curved and flat sheet metal with the MagVacu gripper.

The magnet function is pneumatically switchable and aimed at fast cycle times. A bistable design ensures that you never lose your workpiece, even in the event of a power failure or malfunction.

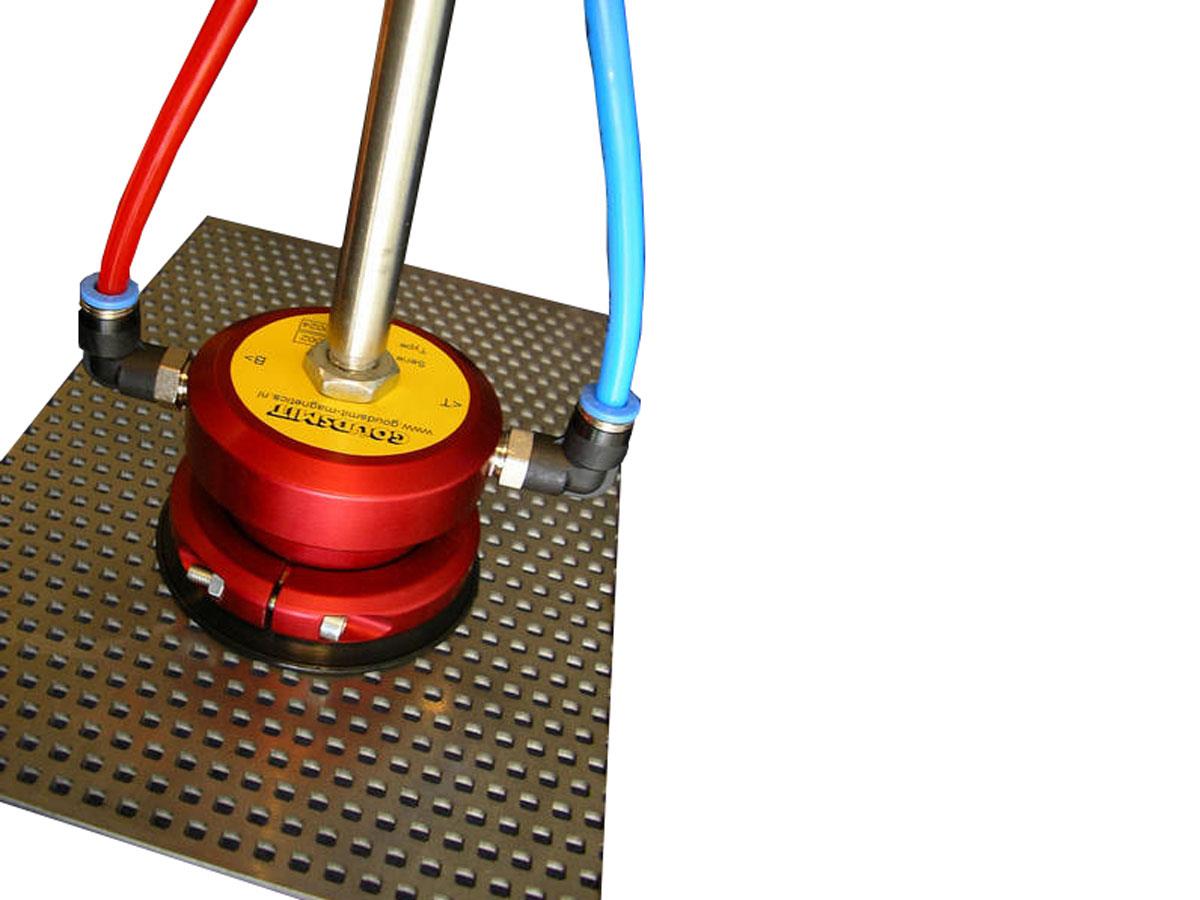

Connection and operation of the MagVacu® gripper

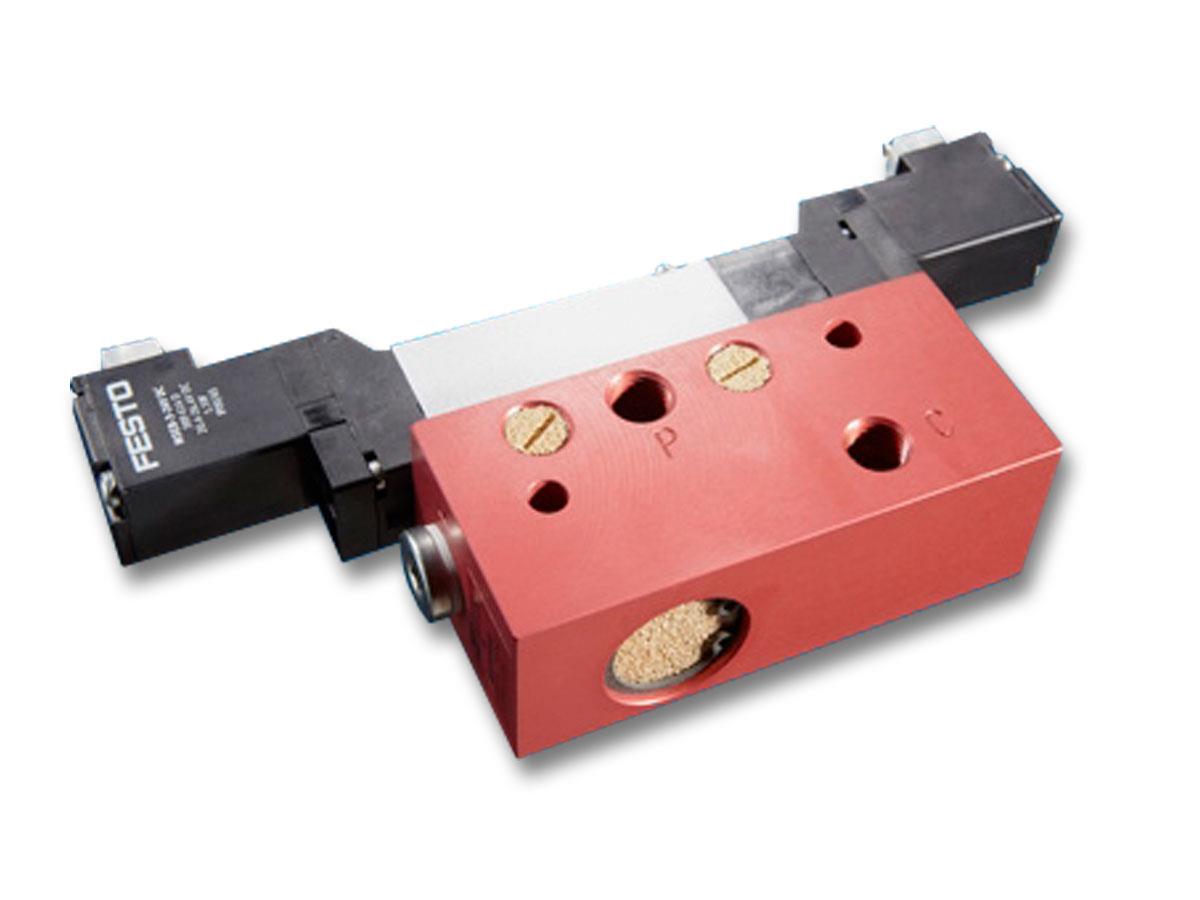

Connecting MagVacu grippers to your robot arm or machine setup is easy with the instructions in our installation manual. The grippers switch pneumatically, so the airflow is regulated with a 5/3 or possibly a 5/2 valve. Goudsmit combi grippers can be equipped with accessories such as a vacuum blow-off valve and spring plungers for extra damping.

Factors affecting lifting force

MagVacu grippers are designed to handle both non-ferro and ferromagnetic workpieces. The achievable magnetic holding force depends on the properties and the chemical composition of the material to be handled. Compared to low-carbon steel, the holding force of magnetic grippers may be lower with other materials:

| Material | Efficiency |

|---|---|

| Non-alloy low-carbon steel (<0.3% C) such as Fe 360, Fe 510 | 100% |

| Non-alloy carbon steel (0.3 – 0.5% C) such as C15, C45 | 80 – 90% |

| High-carbon (0.5 – 1.8% C) alloy tool steel | 70 – 80% |

| Magnetic stainless steel (ferritic, martensitic) such as AISI430 | 60 - 75% |

| Cast iron (>1.8% C) | 45 – 50% |

| Nickel | 10% |

| Stainless steel AISI304 | 1 - 3% |

| Austenitic stainless steel such as AISI316, brass, aluminium, copper | 0% |

In addition to the workpiece material, these factors also reduce the holding force:

- An air gap between the workpiece and gripper. Non-magnetic surface layers such as coatings, foil, rust, dirt, but also rough surfaces lead to an air gap and reduced the holding force.

- Contact surface. When the workpiece is in full contact with the magnetic poles, the maximum holding force is reached. With partial coverage or reduced contact, for example because the workpiece is perforated or hard to touch, the holding force decreases.

- The thickness of the workpiece. When working with thin plates (≤1 mm), take the 'peeling effect' into account. This reduces the maximum breakaway force. In this situation, it is better to make a construction with several smaller grippers (for example 40 mm) than one or two large grippers.

- Temperature. Both a higher ambient temperature (>30°C) and a higher product temperature (40 - 80°C) reduce the magnetic force.

- Acceleration forces. When the workpiece moves quickly, acceleration forces can negatively affect the holding force. Always ensure that the acceleration forces on the workpiece are significantly lower than the holding force.

- Stiffness or flexibility of the load. Long or flexible loads can sag. The deflection effect on the magnet significantly reduces the holding force. Provide enough magnetic grippers at multiple gripping points to prevent sagging. Also provide a flexible suspension of the magnetic grippers to absorb the deflection.

Combining magnetic and vacuum force

Doubting whether your production environment will limit magnetic forces and holding power? Goudsmit’s MagVacu system allows you to combine two forces. If you would like to know more about lifting forces and possibilities, please consult a Goudsmit specialist.

The MagVacu magnet/vacuum gripper is suitable for handling both ferromagnetic and non-ferro workpieces, such as stainless steel or aluminium plates. This gripper combines vacuum technology with magnetic force. You can use MagVacu combi grippers if you don’t want to keep changing end effectors. This way you can grab different materials with one gripper and save valuable time.

MagVacu grippers are the ideal solution when you are looking for flexibility in your production line.