Add-on chute magnets

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

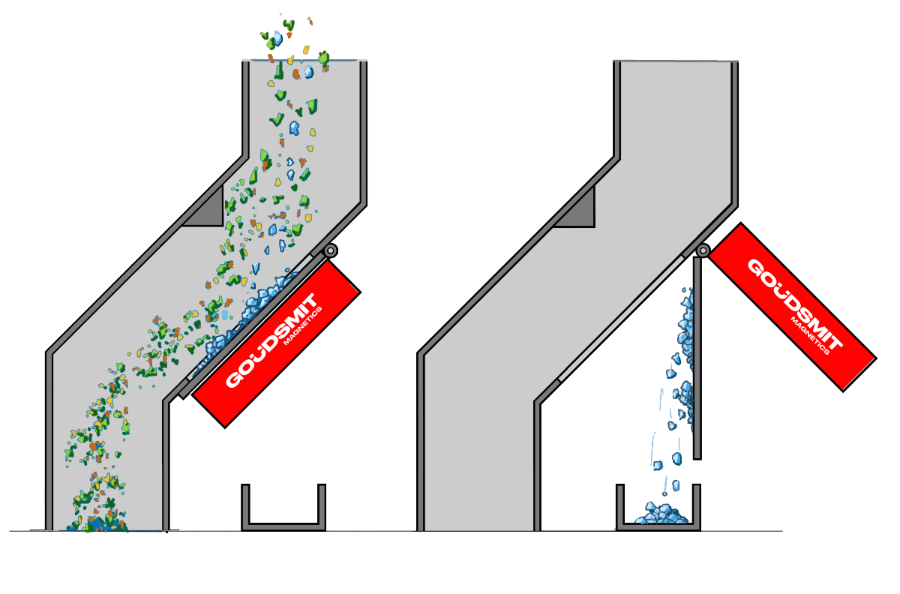

Application: free-fall and chute transport

Add-on chute magnets are mainly used for removing ferrous contaminants from powders, granulates, and even coarser raw material flows in free-fall pipes or chutes with a sliding angle of max. 45˚.

Magnetic chutes are a simple solution for removing iron contamination. You can easily install them yourself, and they deliver a high separation efficiency. We default use neodymium magnetic plates, because they are extremely powerful, compact and lightweight.

Construction & materials data

Add-on chute magnets have robust neodymium magnetic plates that are placed behind a stainless steel extractor plate. 2 quick-release fasteners clamp the magnet with extractor plate against the pipe channel.

- Materials system and magnet casing: stainless steel

- Finish: grit blasted,

- Material seals: EPDM, FDA-approved

Cleaning: filtering & discharging of ferrous contaminants

You can clean the chute magnet through use of the hinged extractor plate for quick-cleaning. When you swing the hinged extractor plate away from the magnet, the ferrous particles will fall off of the extractor plate as soon as they are far enough away from the magnet. For reasons of safety, the operator must operate the chute magnets with two hands. The magnets are secured in the outermost cleaning position, after which the operator has both hands free for cleaning.

Add-on chute magnets - or magnetic chutes - are neodymium plate magnets with a hinged extractor plate and a mounting construction for self-mounting the systeem against the wall of your product channel. They are used for removal of ferrous contaminants from powders, granulates, and even coarser raw material flows in free-fall pipes or chutes up to 45°.