Scrap

Robust magnetic separators efficiently separate ferrous and non-ferrous metals from scrap flows. In this way, the maximum amount of marketable quality metal is immediately recovered.

Loss of valuable metals when recycling shredder streams

Cars (ASR and SLF), WEEE, refrigerators, brown and white goods, electric motors, transformers and aluminium construction materials are shredded for recycling. This always creates a mix of metals, plastics, wood and glass. On the face of it, it would seem easy to separate and sell the iron. In reality, this is far more difficult: the iron is not clean enough and a huge pile of waste is generated. The iron parts contain too high a copper content, with many valuable materials also remaining in the valuable waste. Even already concentrated metal streams often still contain contaminated metals and non-metals. These have to be removed before melting.

Marketable iron fractions with specialist magnetic separators

For the end result, the combination of the right magnetic separator with the different processing steps is crucial. We know from experience how these material flows behave. With this knowledge and our pioneering magnet technology, you create marketable iron fractions. We adjust the specific magnetic separator to the quality and quantity of the metals offered. This results in optimal separation and therefore:

- better circularity;

- lower ecological footprint (carbon footprint);

- less waste to be disposed of.

Together with the right density separation techniques, our magnets also rid mixed metal flows of contaminated metals and non-metals, which must be removed before melting. For example, for the reprocessing of non-ferrous mixes from incinerator slags.

For the further processing of iron particles that are released during the deferrization of the aforementioned metal mixes, we refer you to Ta-Po’s ferrous separator. It was designed together with Goudsmit for this specific purpose.

Magnetic separators for selective separation of coarse ferrous metals

Coarse and exposed ferrous metals larger than 1 mm can be easily separated from a metal mix with permanent or electro overband magnets. For large layer thicknesses, electro overband magnets are preferred. For post-processing in smaller volumes, permanent magnets are more cost-effective.

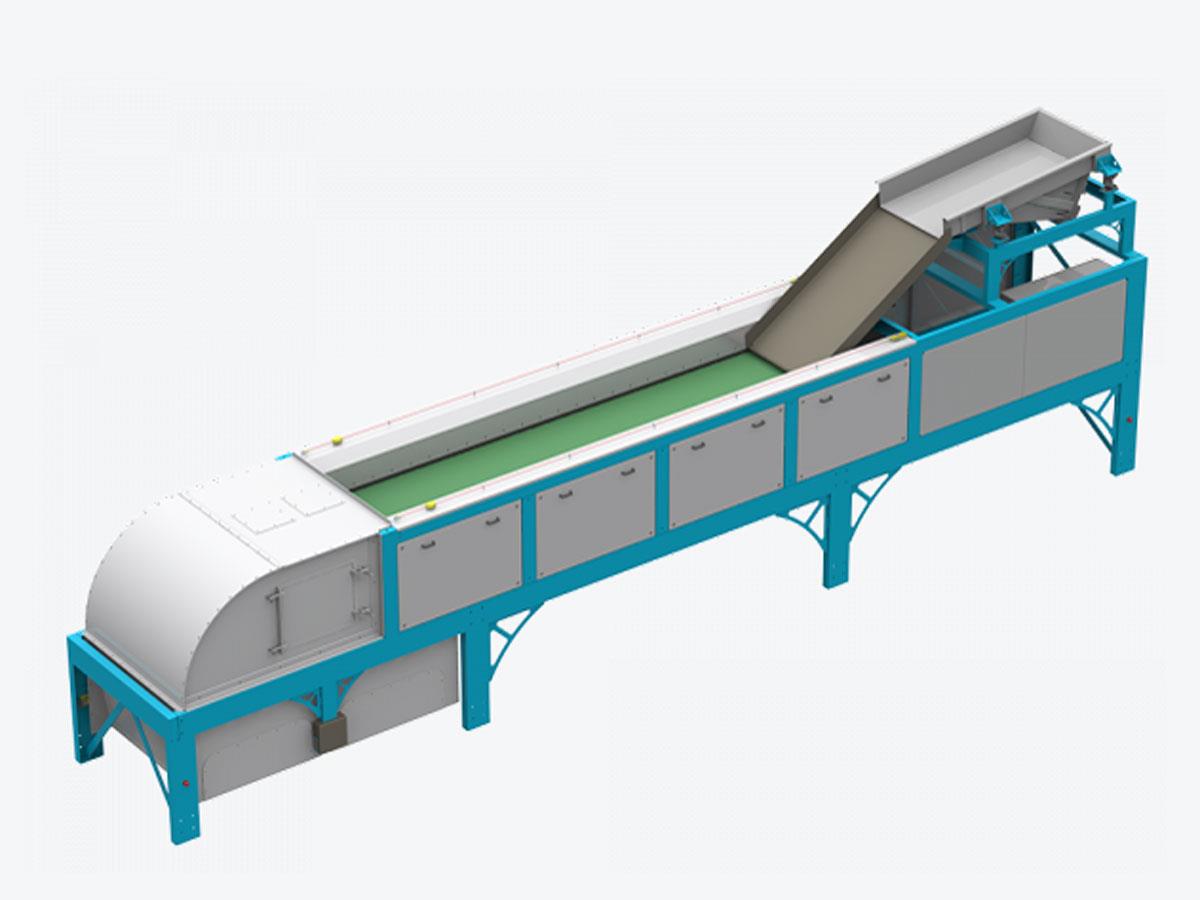

Permanent overband magnets are easy and quick to install above a conveyor belt and require very little adjustment of your production line. This makes these machines perfect as a first separation step for making your shredder flow metal-free. These magnets are therefore often placed directly behind a shredder.

Accurately separating small iron particles and encapsulated iron

Magnetic head pulleys and drum separators of various strengths and for various field depths are available for even more precise deferrization of the various materials. Depending on the type of material, they each have their own effect on the material. To determine the most suitable magnet system, it is important to consider the subsequent steps. Sometimes it is better to choose a lighter magnet, so that your material flow does not lose too many valuable metals. In other situations, a stronger magnet will guarantee the removal of all iron, so that subsequent process steps can proceed optimally.

Easy upgrading of metal flows with extreme magnetic force

Very small ferrous particles are often present as wear particles from the installation itself. These, as well as many types of weakly magnetic material, can be separated by systems with a very strong magnet configuration. One example is the separation of steel and stainless steel from copper granules. Goudsmit delivers ready-to-use high gradient magnetic head pulley systems that make upscaling metal flows easy.

Removing non-ferrous metals with minimal material loss

We often use eddy current separators in metal processing plants because they are very effective in terms of selectivity and capacity. The result is:

- minimal metal loss

- high throughput

- less waste disposal

In this way, your investment will pay for itself quickly. The eddy current technology makes it possible to extract non-ferrous metals as a metal mix from mixed flows. A metal mix can consist of:

- aluminium

- copper

- zinc

- brass

- magnesium

- stainless steel

Goudsmit has several types of eddy current separators that can be easily combined with various kinds of pre-deferrization modules.

Custom advice: the right separator in the right place

At Goudsmit, we strive for optimal separation efficiency, either by using different magnetic solutions in succession, or by combining different separation techniques. For example, magnets in combination with various types of heavy/light separation (density separation) and sensor separation techniques. Pre-testing will prove whether magnetic technology is sufficient. If not, we will let you know in good time.

Every material flow is different, but in the end, every process step results in cleaner final material and therefore an increase in value. At our extensive test centre, we determine the properties of your material. Practical tests provide you and us with quick insight into selecting the right technique. After the analysis, we will gladly advise you which separator to install in which location. In this way, you will achieve the best possible separation efficiency.