Gripping, handling and moving

Challenges in magnetic handling and automation

You want to automate your production process. This prevents production delays, production errors, injuries and other costly accidents. These costly mistakes are key areas of improvement in many industries to compete. Efficiency and sustainability are key competitive factors due to rising energy prices and environmental awareness. Magnet solutions for handling are sustainable and use little energy. Electropermanent magnet grippers, for instance, are more cost-effective than vacuum grippers because they do not require expensive compressed air systems.

With a keen eye for safety, Goudsmit offers a wide range of magnetic solutions for smart automation. We are a supplier to the aerospace, automotive, sheet metal and robotics industries, and are qualified according to ISO9001 and ISO14001. This is how we meet the highest safety and compliance standards, and your expectations.

Magnetic solutions for production, assembly and packaging automation

With an extensive product portfolio for magnetic handling, Goudsmit is your ideal partner for process automation. By combining high-end electric grippers with sheet separators and timing belt magnetic conveyors, you can quickly transform your workplace. Our skilled engineers and sales & service teams are happy to collaborate with you to improve your unique and smart production process.

Your expert in magnetic End Of Arm Tooling (EOAT)

Well-designed production environments require high-quality end of arm tooling. Magnetic tools that bridge the gap between the robot and the workpiece. Robots significantly increase production speed due to their efficient movement, but the precision mainly depends on the different types and properties of end effectors. Goudsmit's expertise is focused on magnetic end of arm tooling, whereby our strength lies in the production, development and maintenance of a wide variety of grippers.

Speed, precision and smart feedback are important factors in EOAT applications. These directly influence each other’s performance. As the speed of the workpiece increases, precision becomes harder to control and feedback from the sensors plays a more important role. All this to meet the ever-increasing safety requirements of the smart industry.

Automation of bending, laser cutting and welding

Magnetic grippers with pneumatic switching help reliably and efficiently handle heavy or irregularly shaped workpieces. Intended for professionals who want to optimise the performance of their bending cell or laser cutting installation. These powerful grippers are also available in a high-temperature version, for use up to 120°°C.

Goudsmit introduces the electromagnetic E-gripper for fast and accurate gripping of (heavy) ferrous workpieces. The strong, compact and reliable E-gripper makes a compressed air installation superfluous. The high-end gripper for robots and cobots is equipped with a variety of sensors and is therefore THE solution for the smart industry.

Due to the bistable design of the gripper, the workpieces remain suspended even when the power or air pressure is lost.

Loading and unloading of CNC, die cutting & punching machines

Robots can load and unload your CNC machines and punching stations quickly and easily. The precision of robots with magnetic grippers is essential here, especially for CNC machines. They prevent the risk of employees damaging expensive CNC equipment or workpieces. Another important advantage of magnetic grippers is their flexibility. They have a grip on almost any shape or form, as long as it is a ferrous workpiece. Powerful grippers only need a small contact area.

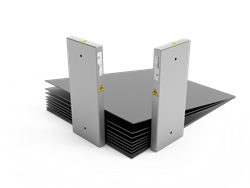

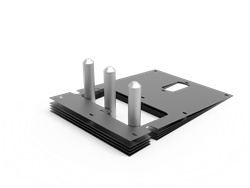

Handling sheet metal

Stacking and handling sheet material is precision work. Flexibility in magnetic holding force is a major advantage here. Also, the smart industry has increasingly high demands for feedback from the grippers to the PLC. Goudsmit produces magnetic grippers that are ideal for companies of all sizes. From individual sheet loaders to storage and distribution facilities, as well as custom production cells. Magnetic grippers can be operated pneumatically or electronically and are available in various models with different holding force and sensor options. In combination with magnetic sheet separators, grippers make it easier to unstack sheets. This is a godsend, especially when working with adhesive sheets or very thin sheet metal.

Palletizing & packaging

We offer permanent palletizing magnets for 24/7 fully automated efficient and safe packaging. These palletizers hold a layer of products easily, without a power supply, only with the use of permanent magnets. Palletizing magnets are designed to fit industrial robots or cranes. They help pack various products such as tins, aerosols, cans, jars with steel lids and steel drums. Palletizers are available in stainless steel or aluminium, are pneumatically switchable and require little maintenance.

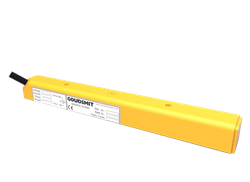

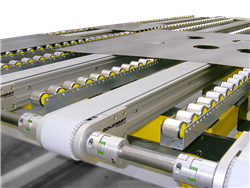

Magnetic conveyors

Magnetic timing belt conveyors can move workpieces or sheet material quickly between production cells or from production machines to packaging systems. The flexibility of magnetic conveyors is evident from the possibility of conveying objects both lying on and hanging under the belt. Goudsmit supplies both electromagnetic and permanent magnet conveyors.

Lifting and moving rough materials

Working with rough material, steel pipes, beams or other oddly shaped, heavy steel objects? Powerful manual lifting magnets are extremely suitable for safely moving heavy loads on the work floor. These robust magnets are used in demanding environments where safety and mobility are essential. We supply the full spectrum of industrial aids such as manual or electrically switched hand-lifting magnets, switchable welding magnets, and much more to optimise your workplace.

Contact us

Do you have any questions or want to know more about our automation magnets? Contact Goudsmit Magnetics today. Our expert team is ready to provide you with advice and support.

Do you want to handle ferromagnetic workpieces safely and efficiently? Magnet systems provide the ideal solution. Both for the automation of your production and for the manual lifting of heavy steel parts. You are always in control with Goudsmit magnet systems.