Static Cleanflow - manual

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

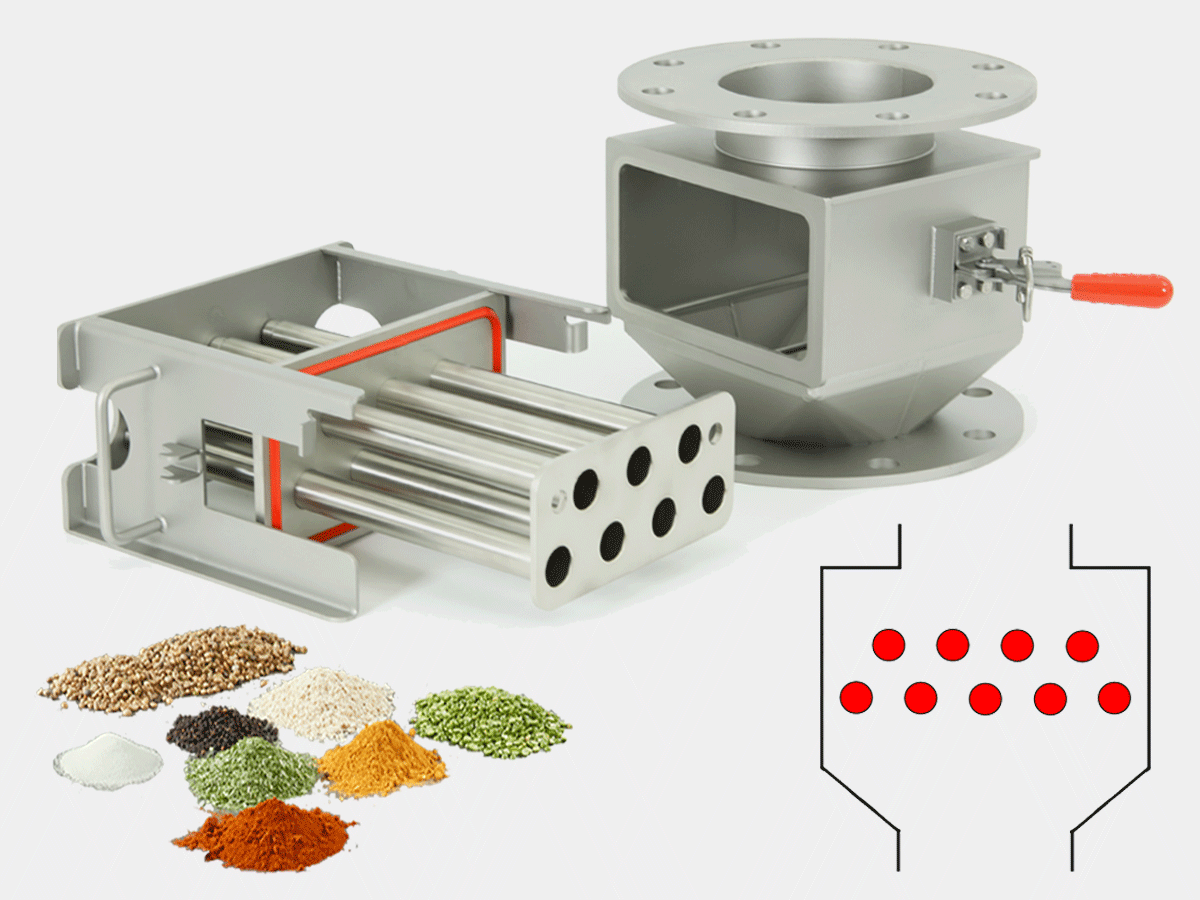

Application: powders & granulates in free-fall pipes

Suitable for magnetic filtering of sporadically present, fine ferrous contaminants from granulates - such as plastics - and dry, free-flowing powders - like flour and sugar - in free-fall transport pipes. NOT suitable for poorly flowing sticky / fatty powders that cause blockages. Rotating Cleanflows are a better solution for those applications.

Construction & materials data

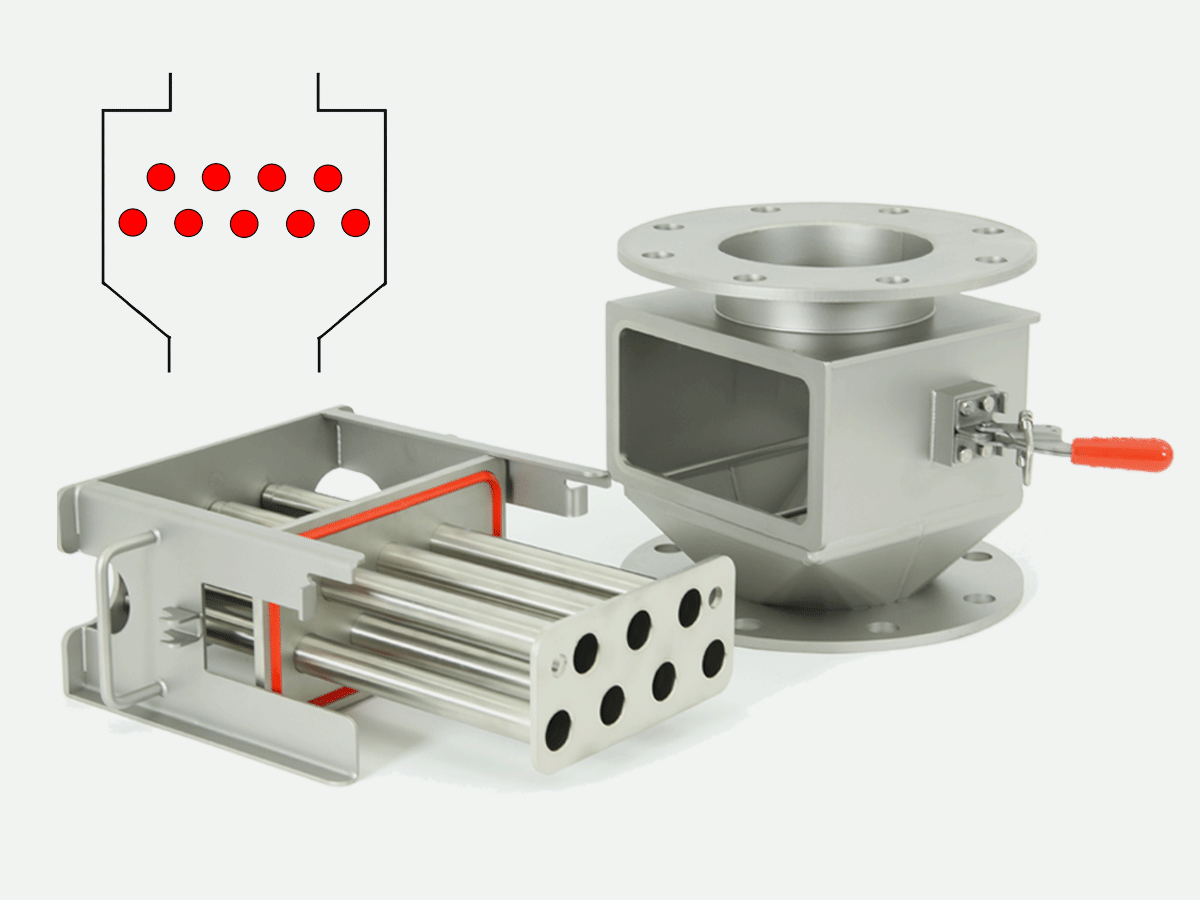

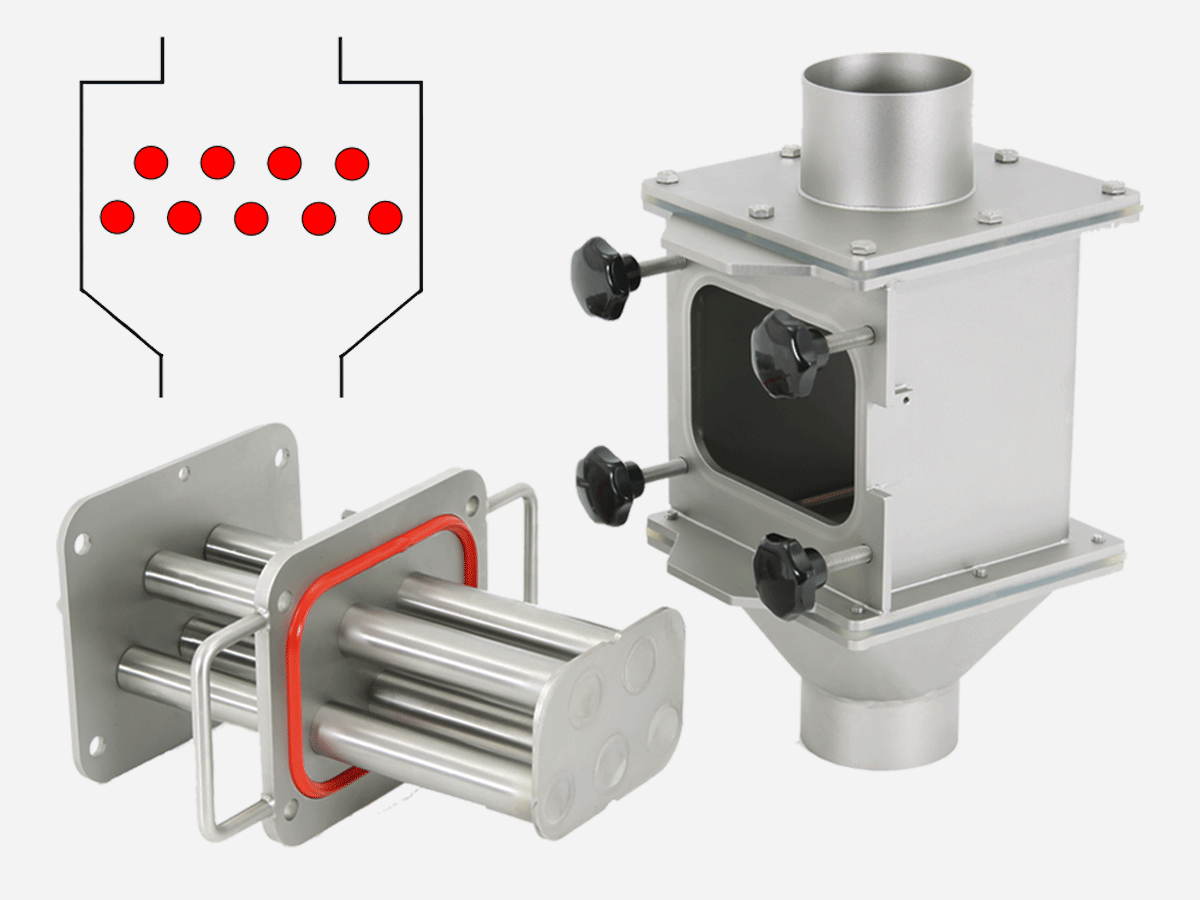

- 2 Magnetic grids, placed staggered one above the other.

- Extractor bars Ø25/Ø23mm for 'quick cleaning'.

- Magnet quality neodymium N-42, 8,000 gauss on tube Ø25.

- Materials - in contact with product: AISI316(L).

- Material gaskets: Silicone EC1935 / FDA.

Available versions, options & accessories

Basic type:

- Industrial execution; grit blasted

- Default with round or square in-/outlet

Food / pharma type:

- Hygienic execution; polished

- Default only with square inlet

Options:

- High temperatures versions - to 140°C - not available in combination with ATEX.

- Steute door safety switch - for detecting if the separator is closed.

- White door seal instead of red.

- Inlet/outlet adapter pieces from square to round.

Filtering & discharging of ferrous contaminants

How does the magnetic filtering work?

The magnetic grids with very strong neodymium magnetic bars are positioned in the middle of the product flow. The product with ferrous contaminants always passes 2 magnetic bars while flowing through the separator. The magnets attract passing ferrous particles. The captured particles stick to the magnets, while the purified product flows further.

How does the cleaning / iron discharging work?

Once the product flow is stopped, you take the entire magnetic grid unit out of the product channel. Then pull the magnetic bars out of the extractor tubes, causing the ferrous particles to fall off the extractor tubes.

Cleaning / iron discharging sequence

- Stop the product flow.

- Loosen the fastener clamps.

- Shove the complete magnet unit out of the housing.

- Take the magnet unit out of the extractor unit and place it away from the extractor unit on a clean surface.

- Catch the ferrous particles that now will fall off the tubes and dispose them.

- Wipe clean all parts with a soft cloth and - if necessary - a suitable cleaning fluid.

- Shove the magnet unit back into the extractor unit.

- Shove the complete magnet unit assembly back into the housing.

- Tighten the fastener clamps.

- Restart the product flow.

For magnetic filtering of small amounts, fine ferrous contaminants from granulates and dry, free-flowing powders in free-fall transport pipes. Industrial and hygienic versions available.