Neodymium plate magnets

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

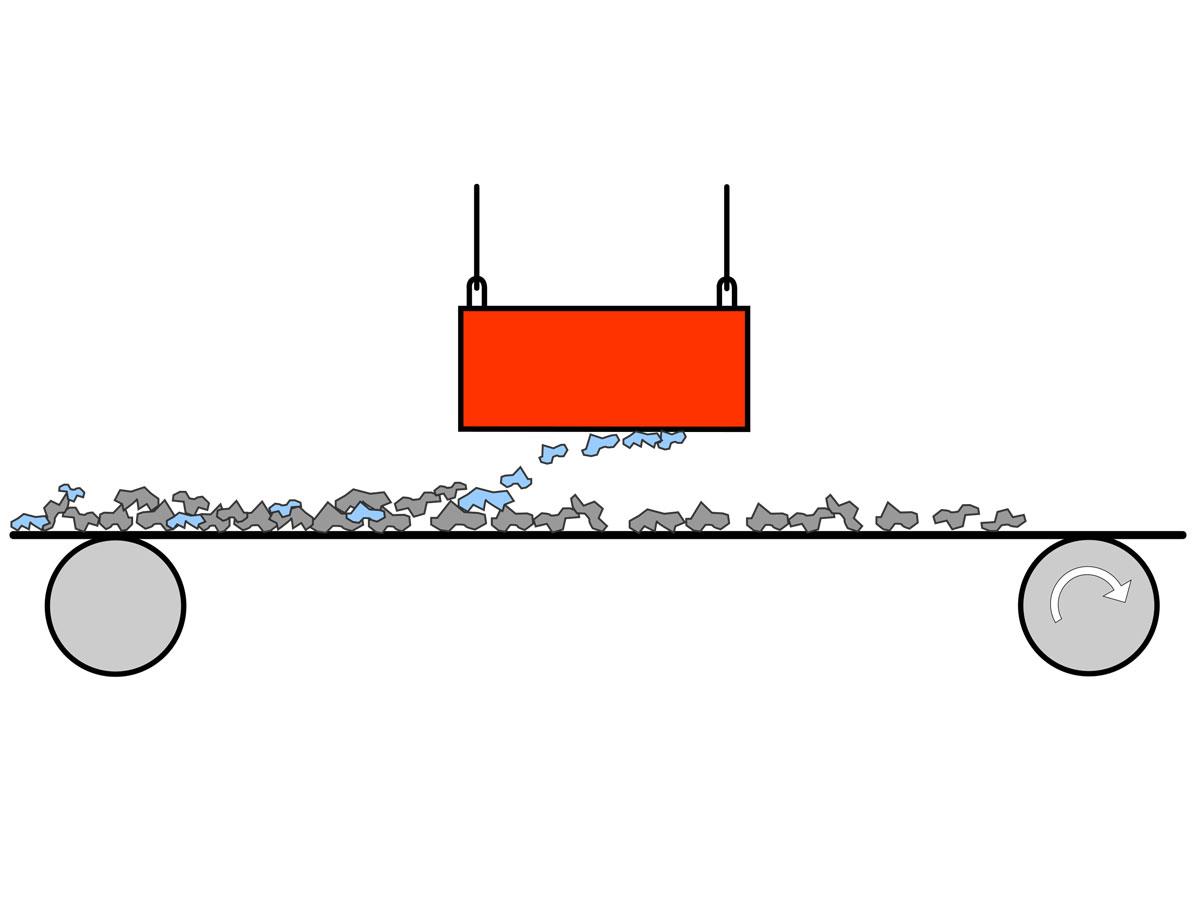

Application neodymium block magnets

Plate magnets / magnetic plates are cost-effective, robust magnets. They are suitable for filtering metal parts from free-fall product flows or products on a conveyor belt with relatively little Fe contamination. Permanent plate magnets can be easily built into existing installations. In this way they protect processing machines reliably and economically, which prevents downtime of production processes. The effectiveness of plate magnets varies from 70 to 90% iron depletion. If an even cleaner product is desired, several magnets or magnet systems can be used in succession.

Placement neodymium block magnets

- Overbelt placement or installation in/against a free-fall line. For placement in a free-fall line Goudsmit also supplies mounting plates (see also chute magnets). This makes dust-proof mounting possible and makes them easy to clean.

- For a width in excess of 300 mm a neodymium magnet is recommended for installation in a free-fall line. In such applications ferrite plate magnets are too heavy for manual cleaning. If you are considering overbelt placement, keep in mind that the construction directly beneath the magnet must be made of non-magnetic material.

Design neodymium block magnets

Goudsmit builds plate magnets for mounting above production lines that feature 'flux control' to create a deeper holding field. These have extra magnets between the poles that cause the lines of flux to penetrate deeper into the product flow. A ridge prevents captured iron particles from being carried away again by the product flow.

Cleaning of neodymium block magnets

Cleaning of the plate magnet is performed manually (by wiping) or through use of an extractor plate (quick cleaning). Hereby you swing the extractor plate away from the magnet. The Fe particles fall off of the extractor plate as soon as they are moved far enough away from the magnetic field. For quick cleaning, see also chute magnets.

Neodymium magnetic plates are extremely powerful, compact and lightweight. They are suitable for separation of ferrous contaminants from 30 µm to 3 mm. Completely stainless steel and watertight. For dry or wet use; also suitable for the food industry. Often used in the recycling industry or for protection of grinding mills.