Rotating Cleanflow - automatic discontinuous

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

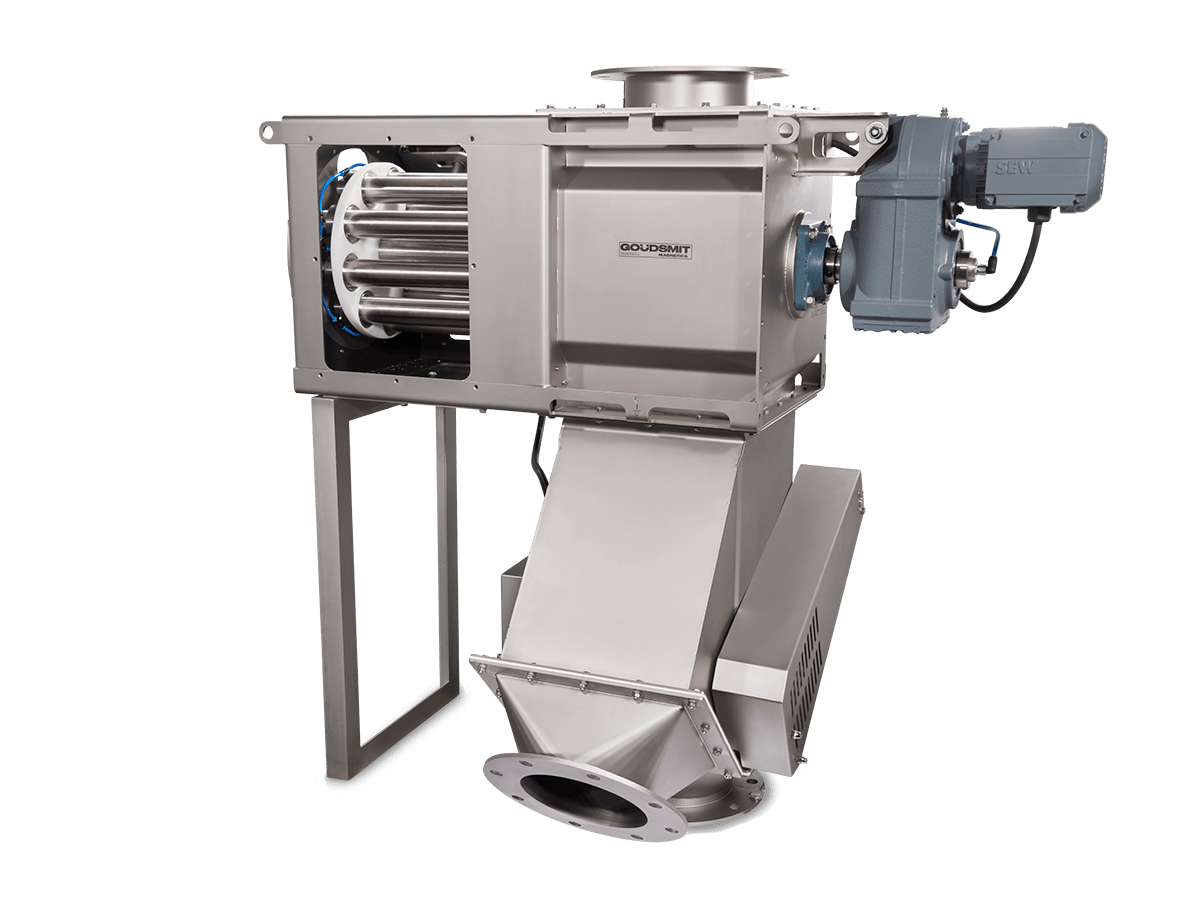

Application: dusty, poorly flowing powders

The rotating, automatically cleaned Cleanflow magnets are very suitable for dusty and poorly flowing - like fatty - powders. The automatic cleaning makes them also suitable for situations where the magnetic separator is hardly or not accessible for operation and cleaning.

Construction & materials data

These completely dust-tight, rotary Cleanflow magnets contain a rotor with magnetic bars. The magnetic bars are Ø34 mm sealed stainless steel tubes inside of which very strong neodymium magnet bundles move pneumatically in and out.

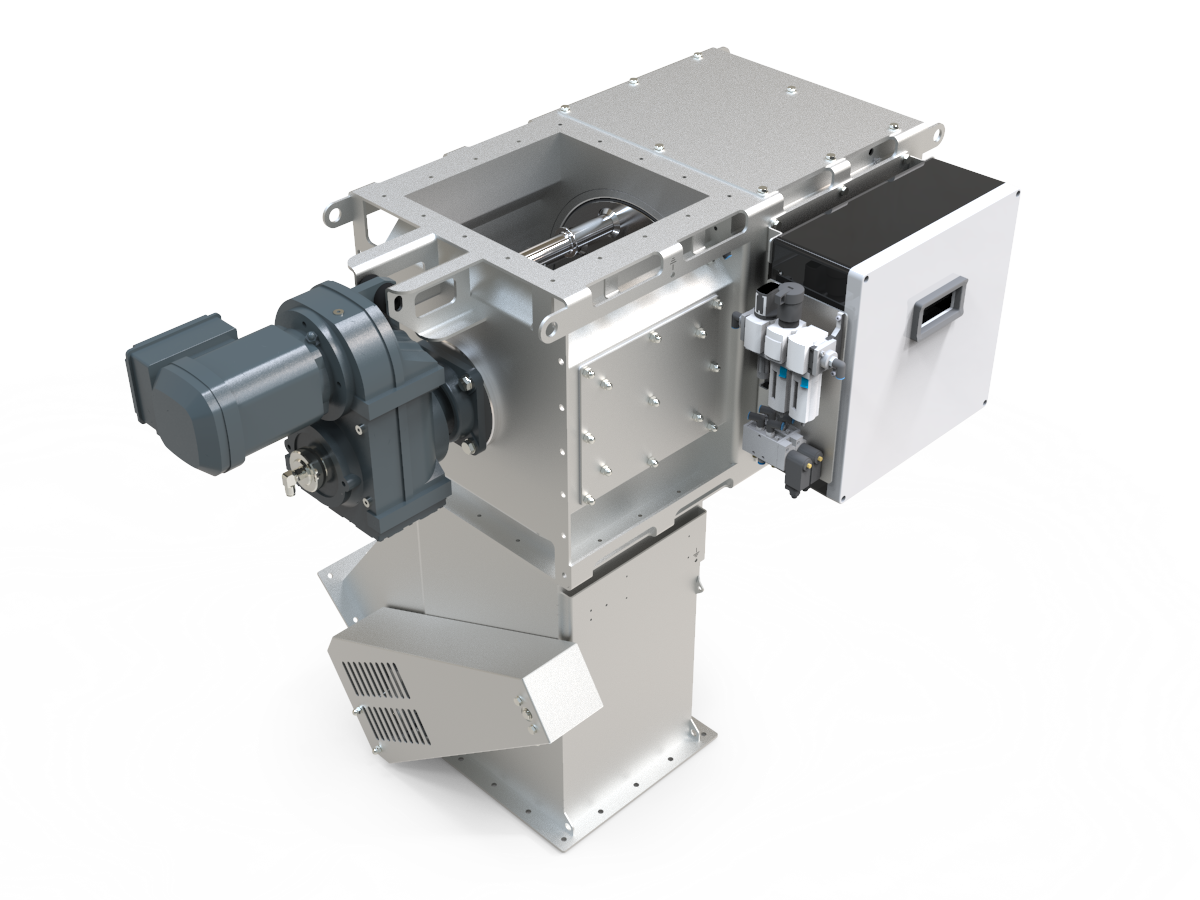

- Siemens LOGO control or Sigmatek control

- Ø50 mm pneumatic operated magnetic bars mounted in a rotor

- Pneumatic bar and valve movement

- Magnet quality: neodymium N-52, 12,000 gauss on tube

- Material housing and rotor: AISI304 / AISI316L

- Finish: grit blasted

Working principle: trapping & discharging of ferrous contaminants

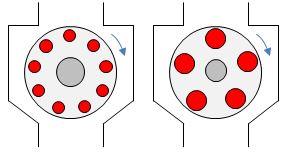

These automated cleaning Cleanflow magnets have a rotor with several pneumatically operated magnetic bars. Each magnetic bar has a magnet package that pneumatically moves inside an enclosing tube.

During a cleaning cycle, the magnet bundles are pneumatically moved out of the product channel. The moving magnets pull the captured ferrous particles along with them over the tube surface. However, they are stopped by the housing side plate halfway the tube length. As soon as the magnets are far enough out, the captured ferrous particles will fall into the product channel, after which the valve box ensures further discharge.

Cleaning sequence

- Stop the product stream.

- Give start signal to the magnet's control unit.

- Now first the valve in the valve box is automatically switched to iron discharge position.

- Then the magnets inside the pneumatic tubes are moved automatically out of the product channel.

The captured metal particles want to 'travel' with the magnets, but are held by retainer rings on the magnet bar tubes. As soon as the magnets are out of reach, the captured particles automatically drop off of the tubes, into the valve box, where they are discharged further. - Then the magnets inside the pneumatic tubes are moved automatically back into the product channel.

- Then the magnets are all back in, the valve will automatically be switched back to its production position.

- As soon as the magnets and valve are back in production position, the control will give a 'ready for production' signal

- You can now safely resume production.

This Cleanflow type is completely dust-proof. For magnetic filtering of small amounts of ferrous contaminants from poorly flowing - like fatty - powders in free-fall transport pipes. The rotation of the magnetic bars prevents bridging and blockages.