AlNiCo magnets - custom

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

The right AlNiCo magnet for your application

AlNiCo is a highly heat resistant magnetic alloy. They are especially unique because of their ability to easily demagnetize and remagnetize by means of an electrically conductive coil. That is why these magnets are extremely suitable for sensors, guitar pickups, relays and alternators.

Steps to find the right magnet:

- Select the type of magnet you are looking for

- Request a non-binding quote

- Enter additional information in the comments field

- Send your request for quote

- Our advisers will process your request and contact you.

Alternatively, contact us directly using our contact form.

AlNiCo magnet grades

AlNiCo magnet alloys are available in two types:

- Sintered with BHmax value ranging from 1.5 – 5.25 MGOe

- Cast with BHmax value between 5.0 – 9.0 MGOe.

These different grades can be used to optimise cost, performance and operational temperature resistance.

Click on the above magnets or download the specification sheet of your desired magnet grade here. Alternatively, contact our technical specialists who will help you choose the right magnet for your application.

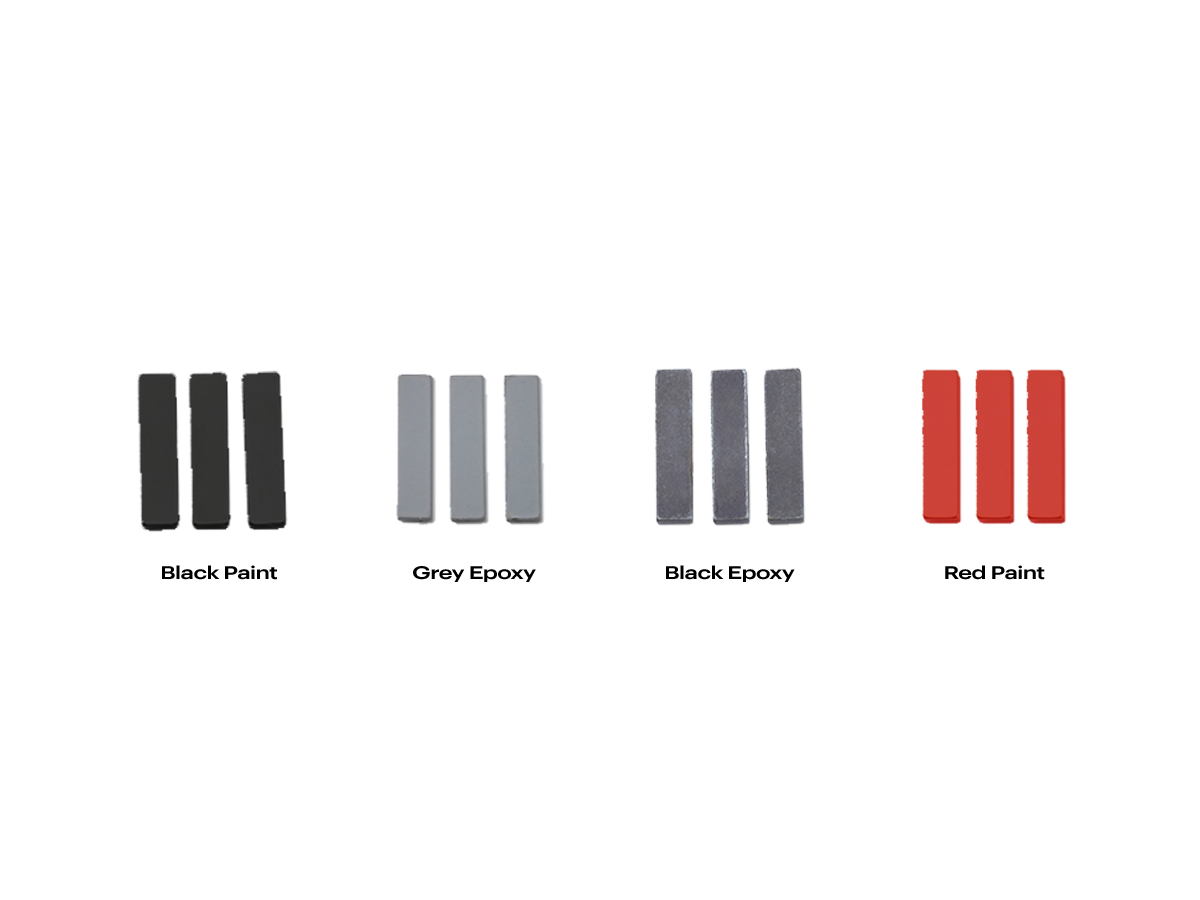

The right coating for protection and manufacturability

AlNiCo is said to have excellent corrosion resistance. The corrosion resistance depends on the quality of AlNiCo and the chemicals it is exposed to. AlNiCo contains some free iron, so it may be susceptible to surface corrosion with water. In contrast, it has excellent corrosion resistance when exposed to engine oil, organic solvents, gasoline and alcohol.

Download our magnet coating selection table. We would be happy to advise you on the options in terms of coating choice. Simply ask your questions by filling in the contact form.

More than just a magnet

The possibilities of magnet technology are endless, but the application can be complex. Goudsmit has more than 60 years of experience in the world of magnetism and is happy to help you with advice and a range of services:

- FEM simulation & magnet calculations: gain quick insight into the operation of your design.

- Prototyping & samples: tangible magnet technology based on your requirements.

- Engineering: development of magnet assemblies and components.

- Quality control: critical properties tested and validated in our own measurement lab.

- Certification: ISO9001.

- Stock management service: delivery of your magnets on demand through our modern warehouse.

Download our product key coding of permanent magnets.

Aluminium-Nickel-Cobalt or AlNiCo magnets are used less nowadays, having been mostly replaced by stronger rare-earth magnets. However, AlNiCo is still used in the manufacture of sensors, guitar pickups, relays and alternators.

AlNiCo magnets play an especially crucial role in all electropermanent magnetic switches and lifting magnets. This is due to the low resistance to demagnetization – and being remagnetized: if electric coils are wound around AlNiCo magnets, they can easily switch on and off magnetically.

Goudsmit offers a wide range of services with regards to the design of the appropriate AlNiCo magnet for your application. For instance, we apply magnet calculations and FEM simulations to quickly identify the best magnet for your product. In addition, we have all the necessary processes in place to supply the automotive & aerospace industries and we follow the IATF16949 guidelines.