Magnetic grids

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

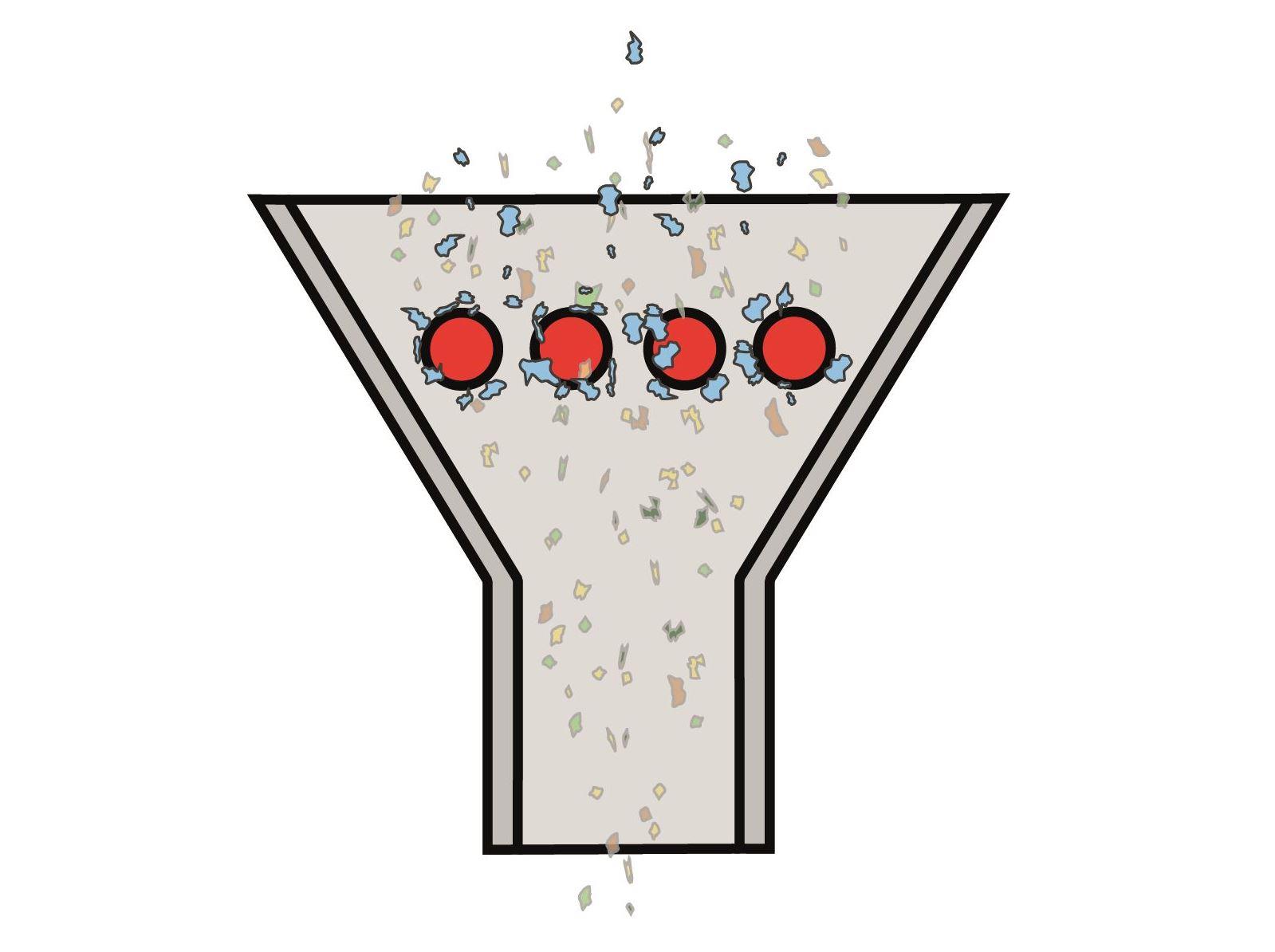

Application: in pouring points, hoppers, as inspection before bagging, etc.

Magnetic grids filter very fine magnetic and weakly magnetic ferromagnetic contaminations from free-flowing powders and granulates. Often used for control purposes. Manual cleaning (quick cleaning).

They are used for applications in the plastics, food, pharmaceutical, ceramics and other industries. In the hopper of your injection moulding machine, for protection of your installation or as final inspection of your product, e.g. just prior to bagging.

Magnetic grids consist of several very powerful Neoflux® (neodymium) magnetic bars. These are located in the middle of your product flow and therefore even capture the smallest ferrous particles, down to 30 microns. Even stainless steel scrapings are captured. These particles are so small that they cannot even be detected by a metal detector.

An effective use is to place two magnetic grids in a cascade configuration, so the product flowing past them must contact the magnetic bars or at least pass extremely close to them. We also use this method with our Cleanflow magnets (grids in housing).

Construction & materials data

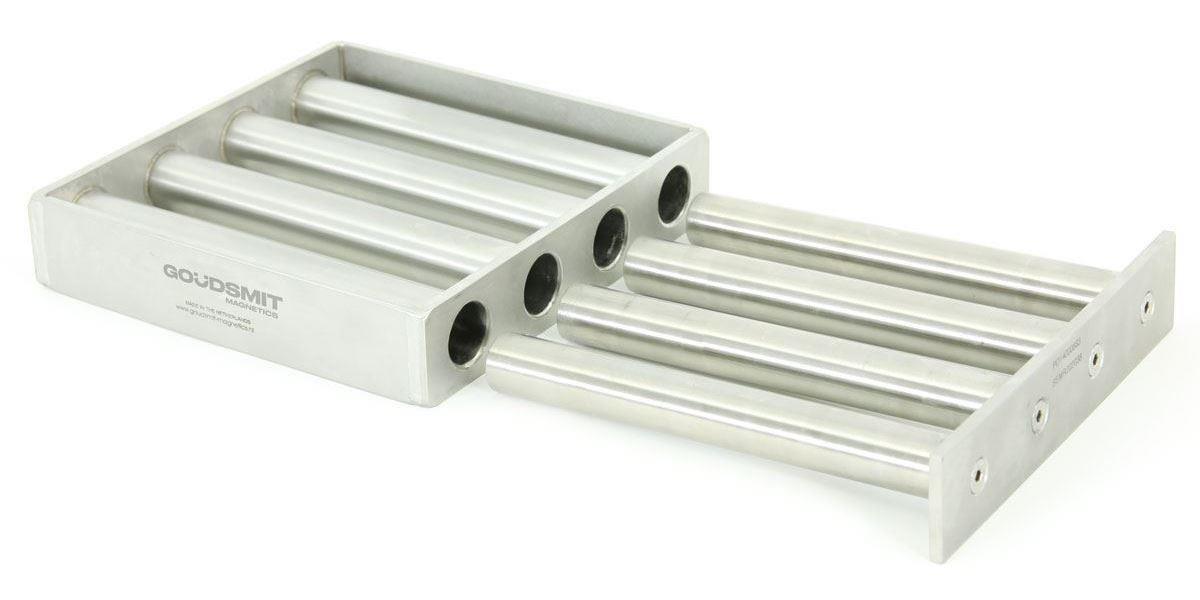

Goudsmit grate magnets are available in square and round. The neodymium magnetic bars are provided with enveloping extractor tubes. This makes the grate robust and manual wiping unnecessary. By pulling the magnetic bar unit from the extractor tubes, the captured ferrous contaminants will fall off automatically. We call this 'manual quick-cleaning'.

The extractor tubes also serve to protect the magnetic bars, making them last longer.

- Magnet quality: neodymium N-42, Br 13,300 gauss (at 20 °C), Tmax. 80 °C. (8,000 gauss on tube Ø25)

- Materials - in contact with product: AISI304 (RVS 1.4301) / AISI316 (SS 1.4401)

Filtering & discharging of ferrous contaminants

The procedure for discharging the filtered ferrous particles is as follows:

- Stop the product flow.

- Remove the entire grid from the product chute or hopper and place it on a pre-cleaned, non-magnetic surface (e.g. wood, aluminium or stainless steel).

- Remove the retainer for the two grid parts.

- Pull the magnetic bars unit out of the extractor housing.

The captured metal particles now fall off the extractor tubes. Make sure you keep the magnet bars away from these magnetic metals during this procedure. - Lay the part with the magnetic bars on another well-cleaned, non-magnetic surface.

Now make sure you also place the magnetic bars far enough away from the magnetic particles. - Dispose of the metal contaminants.

- If necessary: clean all the grid parts with a dry cloth and/or suitable stainless steel cleaning fluid.

- Mount the two grid parts and the retainer.

- Place the grid back in the product chute or hopper.

- Restart the product flow.

Magnetic grids - also called grate magnets - are often placed at a pouring point or receiving hopper. They filter very fine magnetic and even weakly magnetic ferrous contaminants from free-flowing powders and granulates. Often used for control purposes. Manual quick-cleaning by extractor.