Suspended electromagnets

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

Application of suspended electromagnets

Suspended electromagnets have a very deeply penetrating holding field. This makes them very suitable for larger capacities. Electromagnetic suspended magnets can be switched on and off. This simplifies cleaning (when the magnet is switched off the Fe particles fall off the block), and they are more flexible as they can be activated whenever the process requires their use. However, electromagnetic suspended magnets do consume power, and they require a control box. They are also less compact than permanent suspended magnets: a sizeable electric coil is needed in order to generate a powerful magnetic field. This makes them less suitable for mobile installations and somewhat more expensive than permanent suspended magnets.

Cleaning electro (block) magnets

Cleaning of the block magnet is performed manually (by wiping) or through use of an extractor plate (quick cleaning). Hereby you swing the extractor plate away, from the magnet; the Fe particles fall off of the extractor plate as soon as they are moved far enough away from the magnetic field.

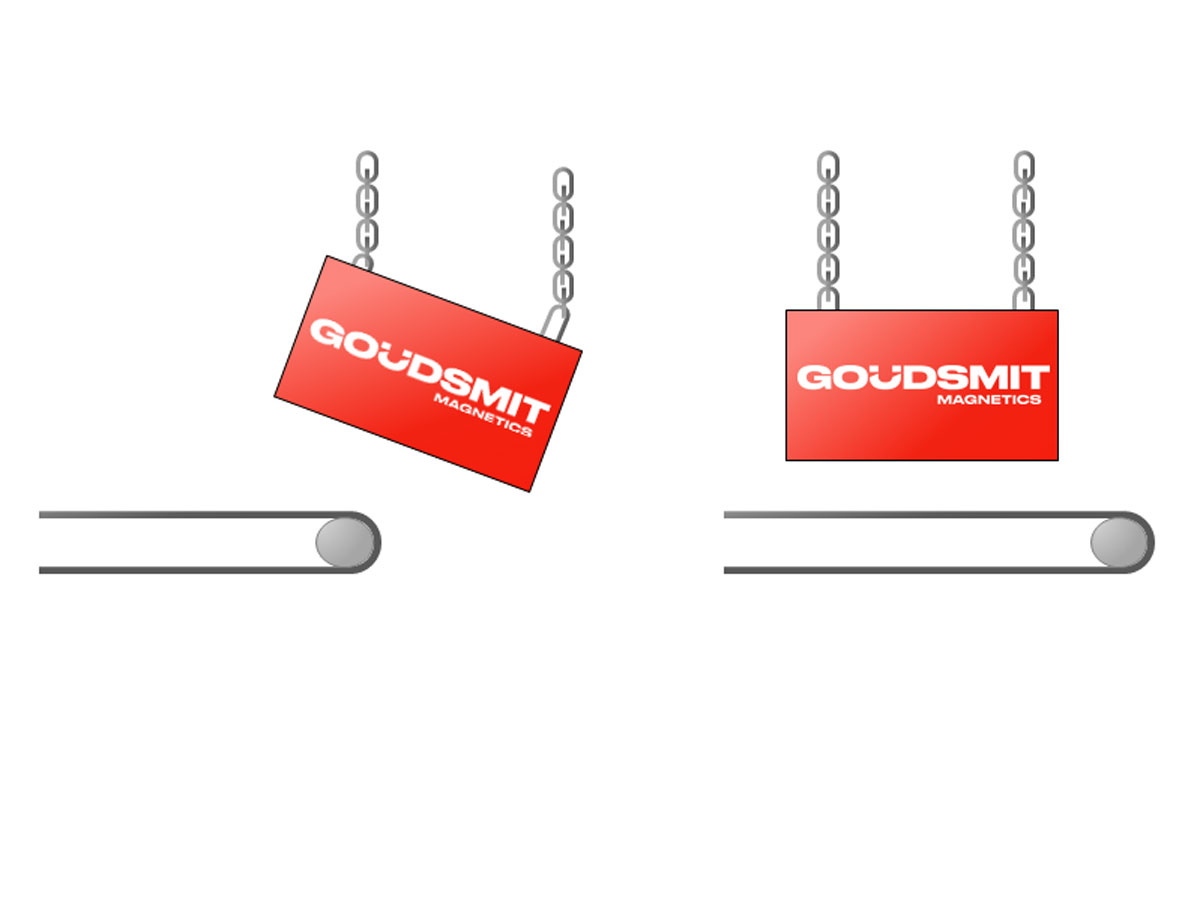

Placement of electro (block) magnets

A block magnet is hung above a conveyor belt, by means of chains or cables. The addition of these magnets can considerably boost separation yield:

- Placement over pulley: In this configuration the magnet hangs at an angle over the end of the conveyor belt, where discharge of the material occurs. This is the ideal situation, because the bulk flow is 'broken open' at this point. When this happens, the iron particles are exposed within the surrounding material. This allows them to be more easily drawn to the magnet. Keep in mind, however, that it is important for the construction directly beneath the magnet to be made of non-magnetic material; otherwise it, too, will become magnetized.

- Placement over band: This position is used for small layer thickness (or mono-layers). Or when there is no other option due to the potential for magnetization of underlying steel components (such as motors or guide rollers).

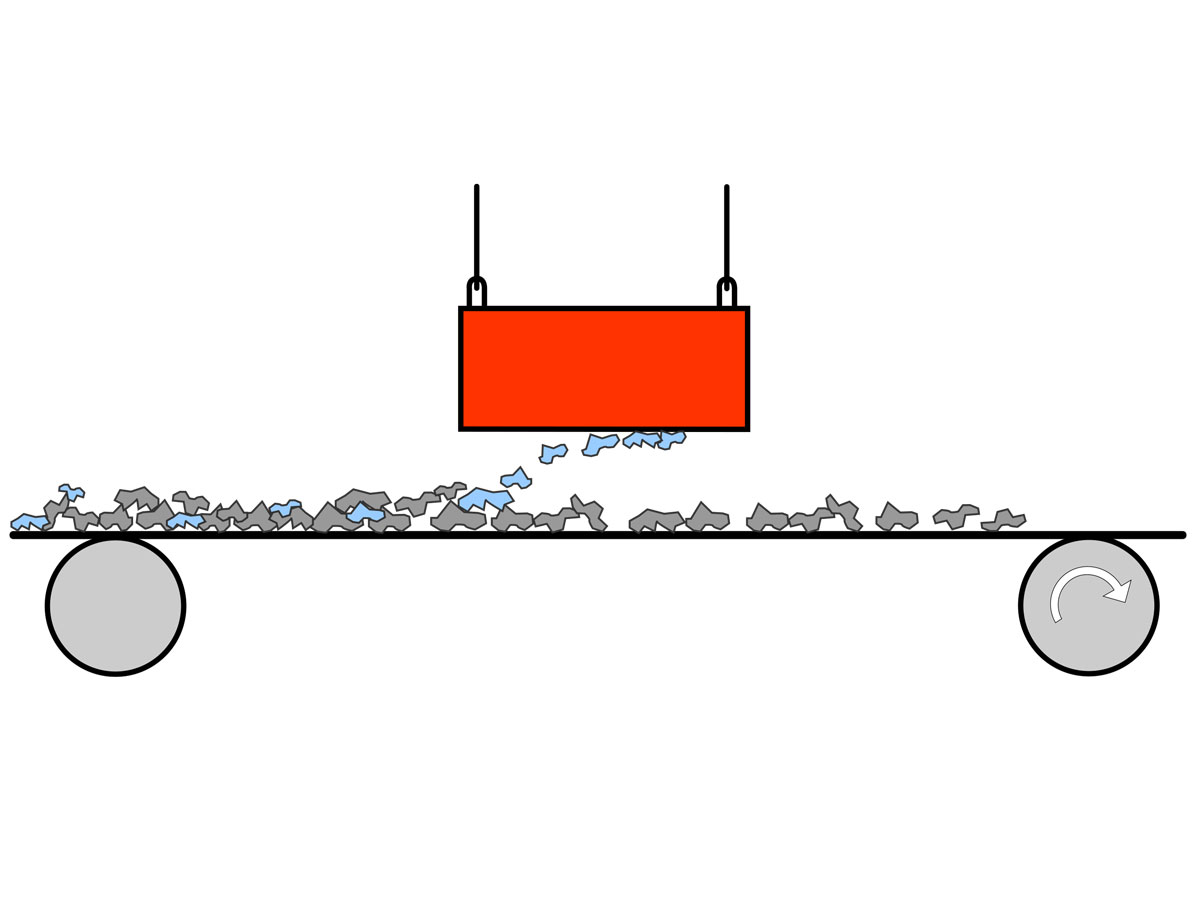

Working principle

Suspended magnets (block magnets) remove undesirable ferromagnetic (Fe) particles such as iron and steel from material flows containing relatively little Fe contamination. They are placed above flat or trough-shaped conveyor belts. The metal particles are drawn out of the raw material flow and held by the magnet. This results in a pure iron fraction suitable for immediate reuse (recycling).

They are used to check incoming product flows and for the protection of machines, such as shredders and sieves. When heavy metal contamination is present, it is better to use an overbelt magnet; This type continuously carries away the iron particles.

Removal of large pieces of steel from bulk flows or in the recycling industry. Suitable for larger installation heights. Can be switched on and off.