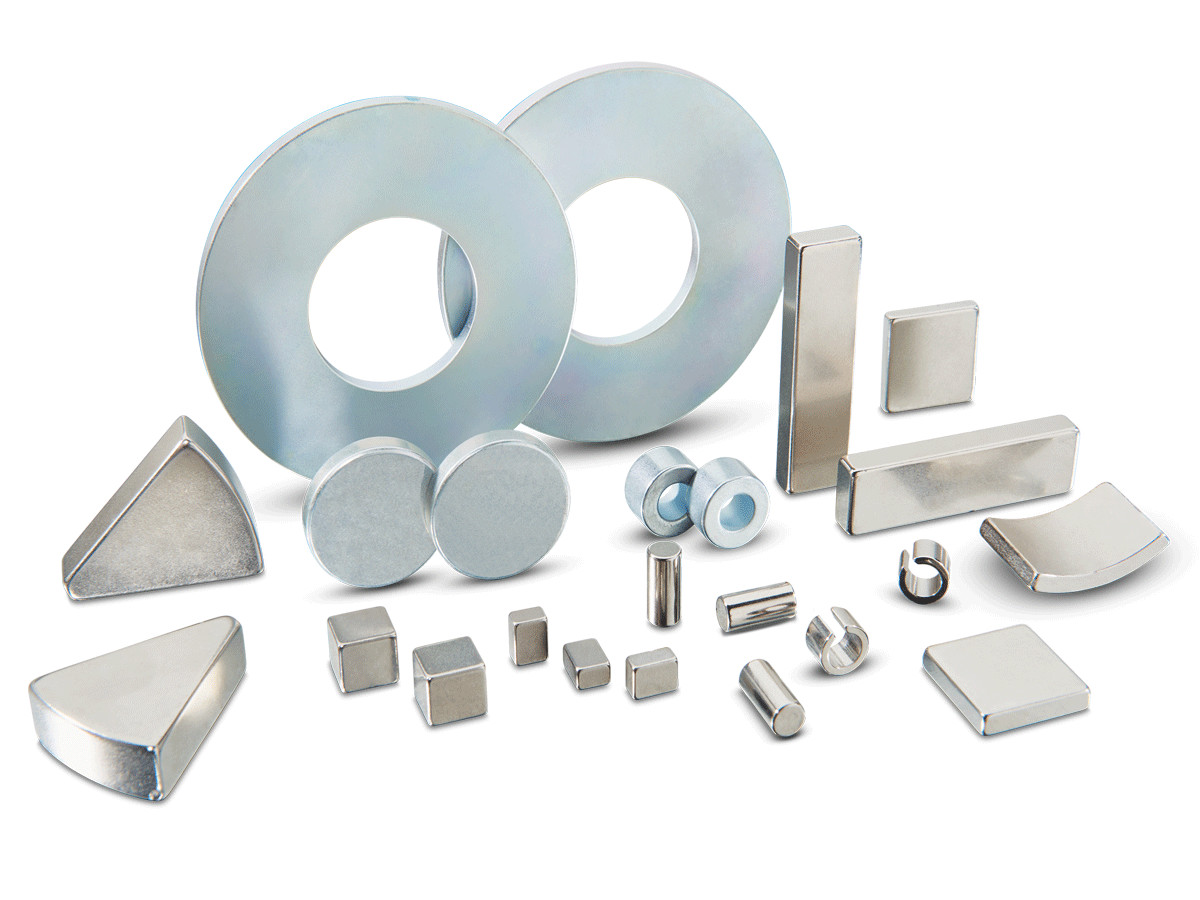

Neodymium NdFeB - stock magnets

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

Why do we use neodymium magnets?

The use of neodymium magnets in high-tech electronics is very popular because of their high magnetic strength and special performance. Neodymium magnets have the highest available magnetic energy density, with a BHmax value of 30 MGOe to 52 MGOe. This strongest permanent magnet is built from Neodymium Iron Borium - NdFeB. Goudsmit Magnetics supplies these magnets under the brand name Neoflux®.

NdFeB magnet qualities

Neodymium magnets are available in different grades, from N35 to N55SH. Each with unique magnetic properties such as Br energy product, HcJ resistance to demagnetisation and temperature resistance.

Click on the magnets above or download the specification sheet of your desired magnet grade for free here. Our technical specialists are ready to help you choose the right magnet for your specific application. Feel free to contact us for advice or more information about our products and services.

How do we prevent corrosion of neodymium magnets and prolong their service life?

Aside from being the strongest, NdFeB magnets also possess less favourable properties. Corrosion, low temperature resistance and mechanical brittleness determine whether this type of magnet can be used within your product.

4 options to improve the service life of NdFeB magnets:

- A coating of nickel, epoxy or parylene, for example, prevents corrosion and prolongs service life.

Coated neodymium magnets are also suitable in extreme conditions. - Through magnetic alloy adjustments, certain neodymium magnets are usable at high temperatures up to 200 °C.

- A magnet assembly prevents chipping or fragmentation. Read more on the magnet assemblies page.

- Plastic-bonded neodymium magnets have a high resistance to corrosion. The advantage of this magnetic product is its manufacturability.

Reliable quality and stable supply

How do we ensure manufacturability, reliable quality and stable supply? The magnetic properties of each magnetic alloy are different. Many manufacturers deliver a quality that does not meet the requirements you set. Over half a century, we have built up a strong network of controlled and certified manufacturers. We assess in advance whether your magnet can be made and whether the desired properties are measurable. In addition to manufacturability, reliability and quality, it is also important that you receive a magnet with a stable price and delivery time

Magnets that:

- Meet the right magnetic specifications

- Are high-quality and reliable

- Are certified and inspected.

Please feel free to download our overview with the product keys for permanent magnets.

Neodymium - NdFeB magnets in stock. Small, lightweight and super powerful. Neodymium magnets are the strongest and most commonly used type of all magnetic alloys. NdFeB magnets are used in: sensors, motors, wind turbines, computers, speakers, medical devices, electronics, and many industrial magnet systems.