High-gradient magnetic head pulley systems

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

Application of high-gradient magnetic head pulley systems

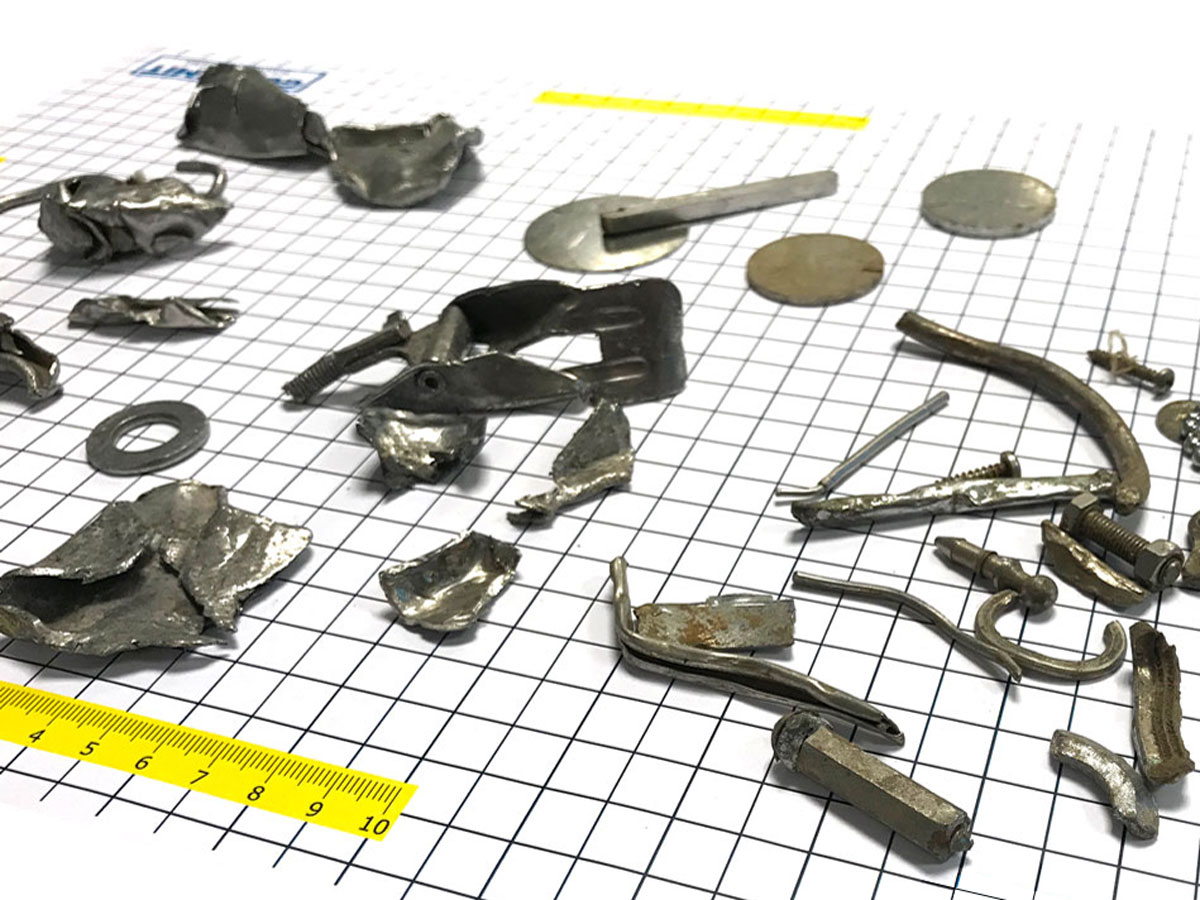

An extra powerful magnetic head pulley with radial magnet construction. Separate weakly magnetic and paramagnetic particles such as stainless steel and steel alloys in small, mono-layer fractions ranging in size from 0 to 40 mm - at low capacities. The high-gradient magnet is used after the separation step for the strongly magnetic ferrous particles.

The total solution is a compact and maintenance-friendly conveyor belt system that can be used for applications such as:

- removing stainless steel rings, springs and balls from shredded plastic bottles with pump mechanism

- removing small metal particles from soil contaminants, soil or stones

- removing smashed pieces of stainless steel from wood recycling processes to protect shredding blades

- separating pieces of stainless steel from shredded WEEE and ASR fractions

- separating iron dust from ceramics or blasting grit

- separating pieces of stainless steel from cable shredder flows before the copper shredder processing step

- separating stainless steel needles from plastic hospital syringes

Design of high-gradient magnetic head pulley systems

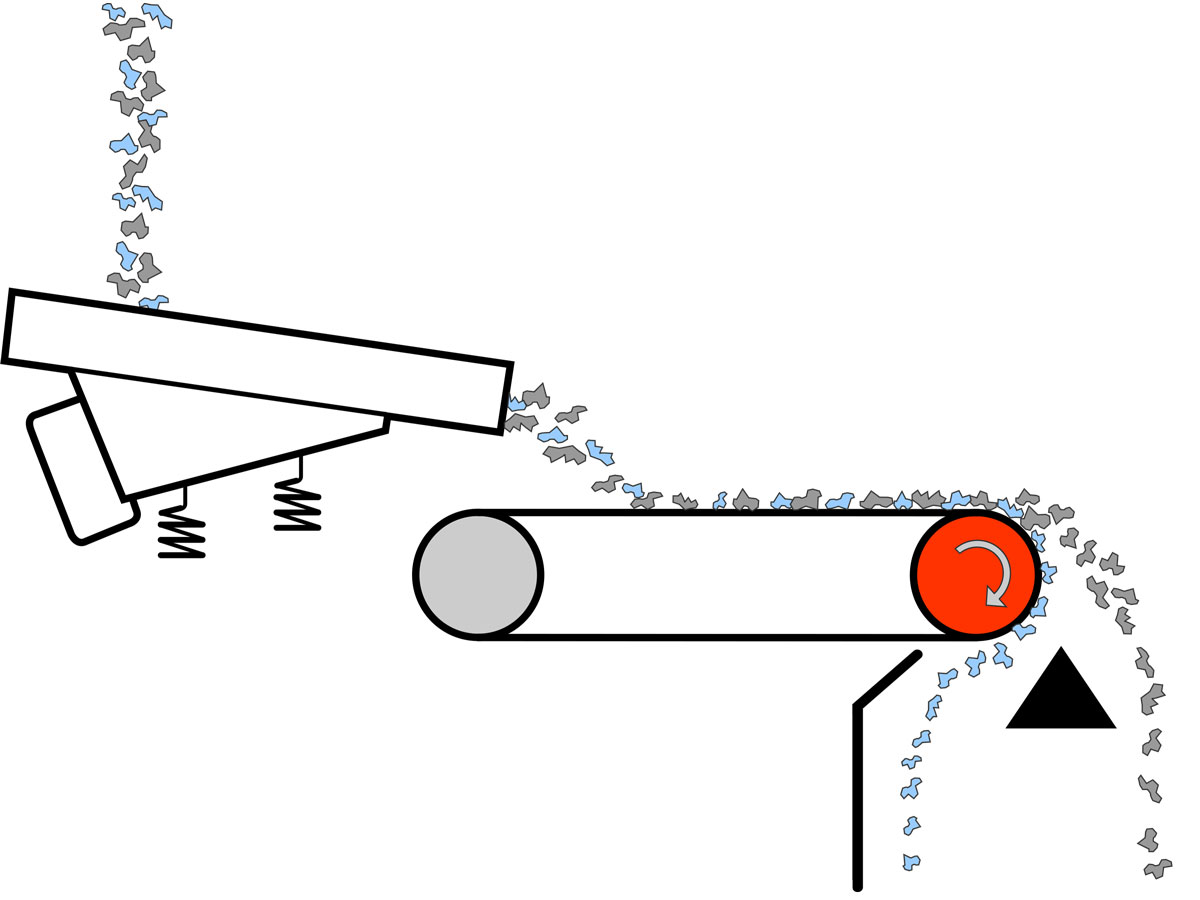

The high-gradient magnetic head roller system can be divided into three segments:

- Supply segment

Vibratory feeder for magnetic head pulley separator This is a stainless steel vibratory feeder, driven by two magnetic linear vibration motors. The vibration frequency is easily adjusted via the supplied control box. Advantages of these motors are the robustness, durability and maintenance-friendliness. - Middle segment

The middle segment contains stainless steel protection covers. This means that the machine requires little maintenance, is easy to clean and can even be used for certain food applications. The sealing strips and wavy edge make product loss impossible. To achieve 9,000 gauss the thin 1.3 mm PU conveyor belt is essential to the functionality of the machine. - Discharge segment

Splitter for magnetic head pulley separator The splitter, also known as a separation partition, ensures the physical separation of the two product flows. The stainless steel splitter is designed to be adjustable both horizontally and vertically. The result: perfect separation, tailored to product flow and capacity. You can optionally choose product hoppers with the machine.

Features high-gradient magnetic head pulley systems

Through the use of high-quality magnets, the high-gradient magnetic head pulley (mounted in the head pulley) has the following characteristics:

- separates weakly magnetic particles > 0.1 mm

- separates ferrous particles > 30 µm (sporadic)

- magnetic field depth 10 mm

- radial magnet construction

- neodymium magnet (10,000 gauss at the shell)

Working principle of high-gradient magnetic head pulley systems

A high-gradient magnetic head pulley system is a conveyor belt system with a very powerful integrated magnetic conveyor roller. This powerful field is created by the combination of neodymium magnets and radial magnet construction. The result: a flux density of 9,000 gauss on the conveyor belt. The high magnetic force is necessary because the crystal lattice of stainless steel does not actually allow magnetism. However, when a stainless steel particle is processed it undergoes a number of plastic deformations caused by shredding, sieving, falling or granulating. These deformations in the stainless steel result in localized material defects in the crystal lattice. This causes the material to acquire slight or weakly magnetic properties. By the time a stainless steel particle reaches the high-gradient separator, its deformation causes it to be between 5 and 10% magnetizable. The need to deflect a weakly magnetic particle from a product flow is why the extra-high magnetic force is needed.

The belt is fed from a vibratory feeder, possibly in combination with a supply hopper. The belt speed is continuously adjustable. This ensures that the product supply (capacity/layer thickness), along with the attracting power of the magnetic conveyor roller and ballistic effect of the product speed, can be perfectly regulated. The splitter separates the product flow physically into a weakly magnetic metal fraction and an inert (non-magnetic) fraction.

A drawback of a high-gradient magnet it that it is so powerful that it also attracts other bits of magnetic material. Such as pieces of plastic, wood or rubber contaminated with iron oxide. This can result in a metal fraction contaminated with undesirable materials. In this case, the obtained product requires further purification to yield a saleable fraction.

High-gradient magnetic head pulley systems are used to capture weakly magnetic particles. Due to the low magnetic field depth, this system is not suitable for high processing capacities.