Paper, fibres and textile

In the paper, fibre and textile industries, steel wires can end up in the pulp. This results from, among other things, the incomplete removal of the binding wires or straps that hold the cellulose bundles together. Steel particles damage costly equipment that further processes the pulp, resulting in a production stoppage. Using a magnet prevents this, both in wet and dry processes.

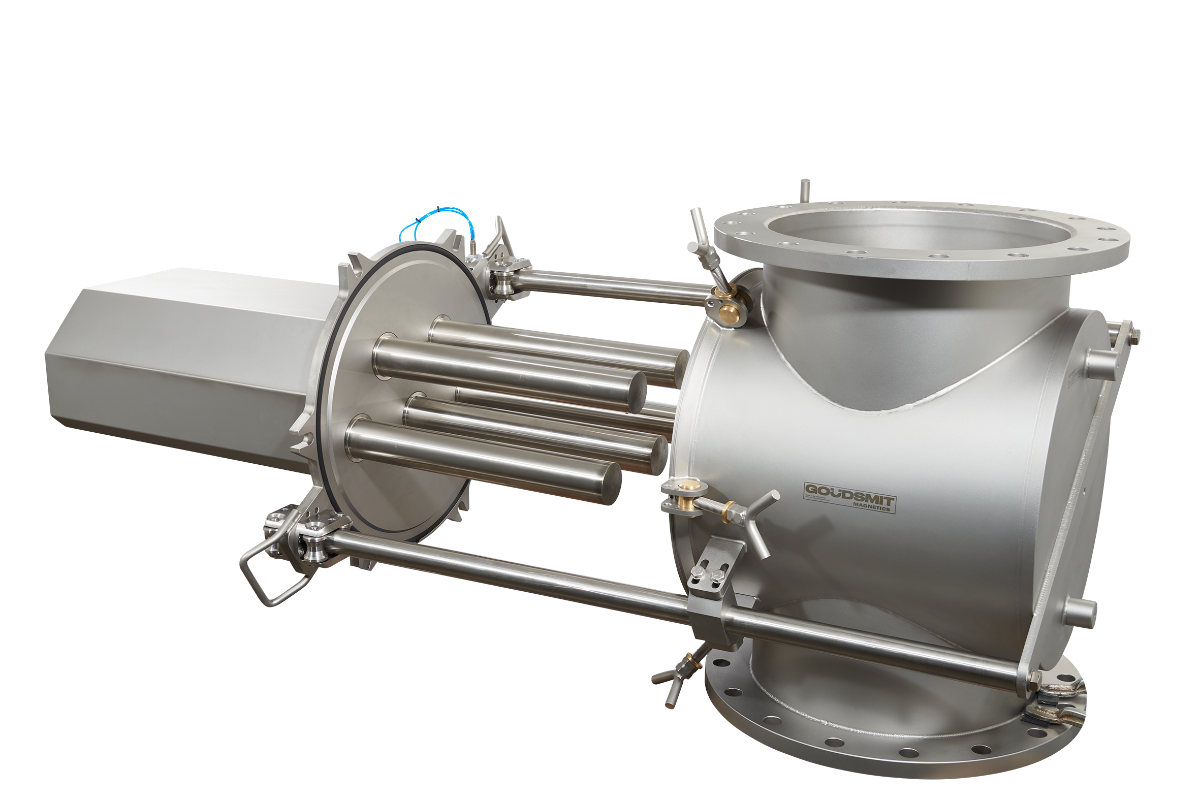

Magnetic filter for paper pulp

A magnetic filter removes iron baling wire from paper that is to be processed for cellulose, and serves as protection for the installation. This prevents downtime in the manufacturing process. Several large European paper manufacturers have now built a magnetic filter into their process.

Safeguard

A magnetic filter is a true ‘safeguard’ and should in all cases be a standard in paper, fibre and textile lines. The filter prevents machine damage and production downtime. That makes the ROI time of such a filter very short. The way in which the iron contamination can be filtered out depends on the structure of the product.

During the production of paper or textile, for instance, the raw material is a tangled jumble. Wetting the product untangles the mass, making it easier to separate the iron.

Goudsmit has therefore developed magnetic filters for both wet and dry processes.