Static Cleanflow - semi-automatic

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

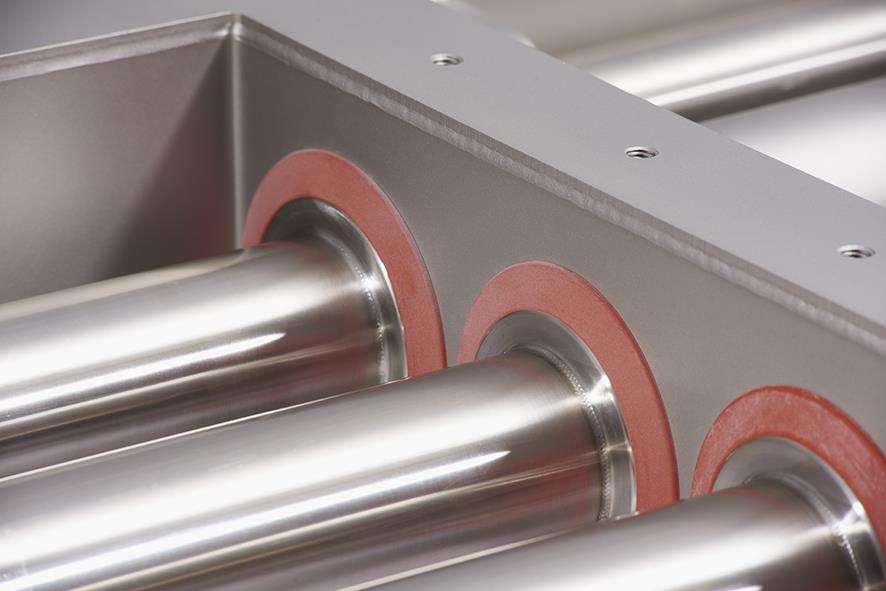

Advantages of Cleanflow magnetic separators

- Maximum efficiency: powerful 12.000 gauss magnetic bars in contact with the product

- Semi-automatic cleaning: fast and easy discharge of metal contaminants.

- Seamless integration: compact design to fit easily into existing production lines

- Closed magnet design: no open-pole system, magnets are fully sealed and protected

- Fully customizable: various options to meet your unique needs

Why choose static Cleanflow magnetic separators?

For industries where product quality and safety are paramount, these separators are an essential solution. They are suited for applications where gravity driven product flow is required, such as in the food, chemical, and plastics industries. By trapping ferrous contaminants before they can affect your product, you can ensure a higher level of customer satisfaction and brand protection.

Applications in the food industry

Static Cleanflow magnetic separators are ideal for various powder and granulate products, particularly in the food industry, where contamination control is essential. Common applications include flour, sugar, spices, dairy powders, and other free-flowing ingredients. By ensuring a clean, contaminant-free product, these separators help food manufacturers maintain quality and safety standards across a wide array of production lines.

How it works

As product flows freely through the separator, powerful magnetic rods attract and retain any metal particles, ensuring consistent performance and ease of operation. The semi-automatic cleaning system makes it simple to remove captured metals, while a variety of customizable accessories (such as a catch-tray for collecting contaminants during cleaning) further enhances usability. This customization allows the separator to meet the specific demands of various industries.

Designed with your needs in mind

These separators are crafted for easy integration and low maintenance, making them the preferred choice for manufacturers seeking quality control solutions with minimal operational interference.

Maintenance and longevity tips

To ensure long-lasting performance, we recommend regular cleaning and inspection of the separator. This keeps it operating at optimal levels and prevents any buildup that might affect its efficiency. The separator’s robust design and corrosion-resistant materials contribute to its durability, and routine care can further extend its lifespan.

Specifications and customization

Available in multiple configurations to meet your exact requirements, Cleanflow Magnetic Separators can be customized to match the specific demands of your production line; these filters can also be stacked and combined in a multi-level set-up.

Simple and efficient cleaning sequence

The cleaning process of the static Cleanflow semi-automatic magnetic separator is designed for efficiency and ease:

- Release magnetic rods from the housing to allow easy access.

- Effortlessly remove any captured metal contaminants with the semi-automatic mechanism.

- Quickly reposition the magnetic rods in their production position.

- Utilize accessories such as the catch-tray for convenient collection of contaminants.

This efficient sequence keeps maintenance simple while maximizing the separator's effectiveness.

Need advice?

Reach out to our experts. We can support you with magnetic calculations, accessories and connection flanges, questions about finishes and coatings, and much more.

Our semi-automatic static Cleanflow magnetic separators are crafted to meet the demands of modern industries. Designed to effectively capture metal contamination in free-flowing powders and granulates, they ensure a higher standard of product purity. Cleaning is semi-automatic and very quick. Last but not least, these separators protect valuable production equipment.