Belt conveyor magnetic separators

Magnetic separators for belt conveyors

Magnetic separators are intended for:

Separation/recovery of ferrous metals

Such as iron, steel and weakly magnetic metals such as machined stainless steel. Overband and suspension magnets are distinctive in terms of service life, robust construction, magnetic force and magnetic field depth.

For product flows with sharp metal parts, where a conveyor belt is a poor choice, we recommend (scrap) drum separators. These are extra robust, which makes them almost maintenance-free and durable. When there is little space available for installation, magnetic head pulleys are the best solution for removing ferrous metals from a bulk or other product flow.

Separation/recovery of non-ferrous metals

Such as aluminium, copper, zinc, gold, silver and magnesium. Eddy current separators separate and sort non-ferrous metals such as aluminium and copper from primary or secondary raw material flows. We often use a combination of these separators one after the other. For the best separation efficiency, the fraction has a certain bandwidth in terms of particle size.

There is an optimal magnet system for every fraction distribution. By strategically placing these in the process line, you can optimally recover valuable metals. Goudsmit’s specialists are happy to advise you on the most effective placement of these machines.

Purifying product flows

With magnetic separators you can purify or clean up unwanted ferrous or non-ferrous parts from (bulk) product flows. For example, shredded plastic bottles/flasks, which contain (stainless) steel balls and springs in the spring mechanism. For a clean, reusable plastic flow, you want to remove these unwanted parts.

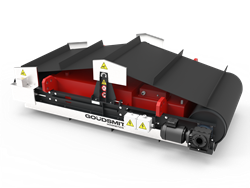

Overband magnets

An overband magnet effectively and quickly separates high volumes of iron or steel and hangs above a flat or trough-shaped conveyor belt - in line or cross belt magnet. An overband magnetic separator is self-cleaning and continuously draws ferro parts from a material flow. The iron removal efficiency of overband magnets ranges from 70 to 90%. This depends on magnet design, product flow and placement.

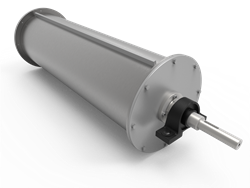

Magnetic head pulleys

Goudsmit can deliver magnetic pulleys as an add-on/build-in roller for an existing installation or we can deliver complete plug and play systems.

Magnetic head pulleys for installation

These magnetic rollers come in different magnetic field strengths, diameters, working widths or shaft types in order to fit your requirements.

Magnetic head pulley systems

These systems are fully equipped in order to adjust everything for the best separation. Make use of the many options to create the best separator for your product flow.

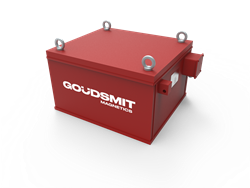

Magnetic drum separators

A drum magnet consists of a stationary magnet segment, around rotates a stainless steel shell with cleats. The product flow falls over the shell, while the magnet attracts the ferromagnetic metal particles in the product. Cleats on the shell carry the captured metal particles to the underside of the drum, outside the magnetic field. There the separated particles drop off and can be collected and/or carried away. This is often achieved through use of a separation plate.

Through the use of various magnetic systems, it is possible to capture both ferromagnetic ('strongly magnetic') and weakly magnetic particles.

Non ferrous metal separators

Goudsmit eddy current separators are robustly built, including a magnetic rotor with an eccentric design. This has a number of advantages over centric systems:

Adjustable magnetic field

The magnetic rotor is internally adjustable: this influences the moment of launching of the non-ferrous metals. For more information about machine adjustment, please contact our application specialists.

Prevent shell damage

Concentric systems suffer from so-called ‘burn in’. This occurs when the product stream still contains iron or ferrous parts that end up under the conveyor belt. The eddy currents heat up these magnetic parts and they burn through the protective jacket. That results in permanent damage. Eccentric systems (almost) do not, because not the entire circumference of the roller is magnetic.

Contact us

Do you have any questions or want to know more about our conveyor belt magnetic separators? Contact Goudsmit Magnetics today. Our expert team is ready to provide you with advice and support.

Magnetic separators sort product flows by separating metals. You can use this to remove metal pollution in raw materials, or recycle reusable metals in product flows. Ferrous separators for recycling/sorting ferrous metals and non-ferrous metal separators for recovering valuable metals. Innovative and high-quality recycling solutions for the most effective metal recycling.