External pole magnets - automatic

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

Application: ferrous separation in free-fall chutes

External pole magnets separate ferromagnetic impurities – such as iron and steel – from 1 to 50 mm, from dry powders and granulates in free-fall chutes. You place these magnets at the inlet and outlet of your process. This protects the subsequent process lines and machines against metal contamination.

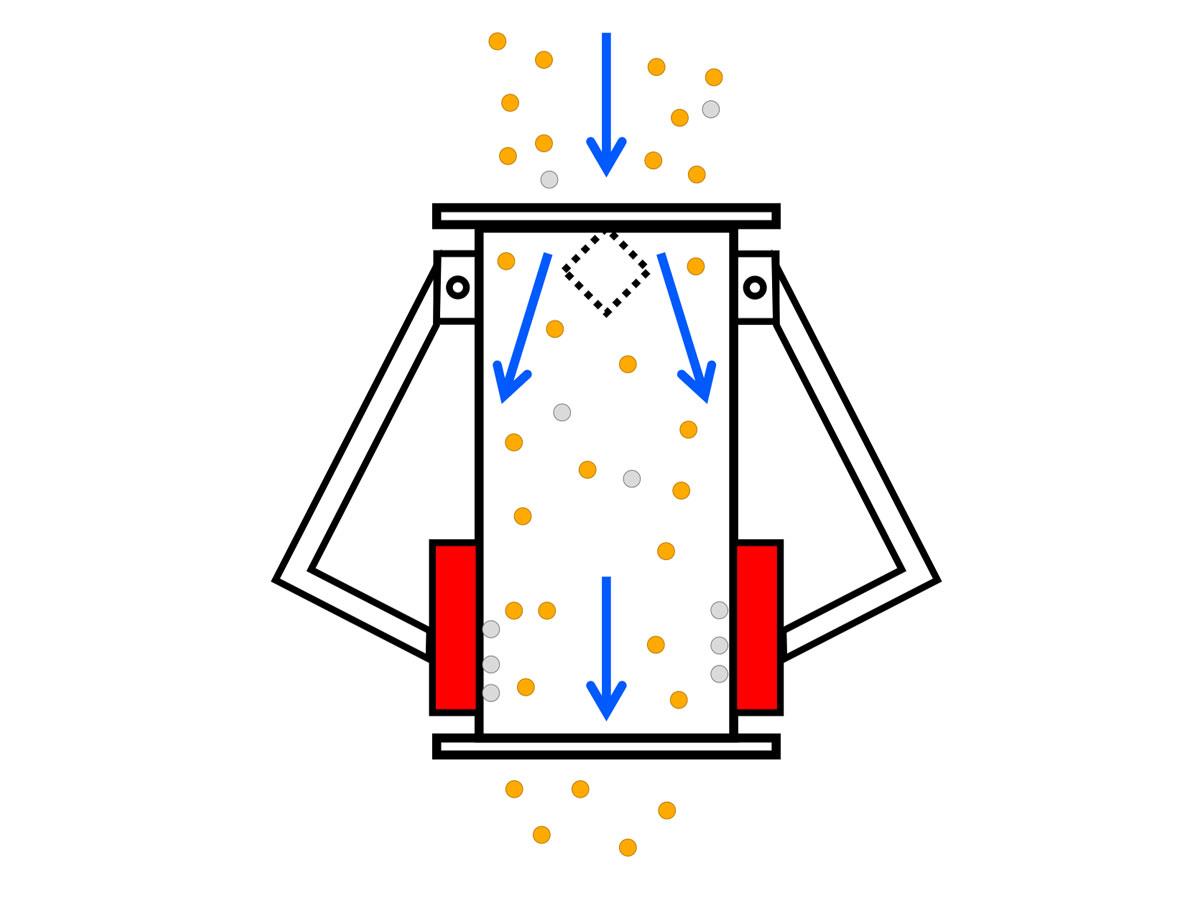

Two powerful neodymium plate magnets are mounted outside the product channel. In other words, there are no magnets in the direct product flow. This prevents bridging or material blockages. The separators are very robust, process high capacities and can capture many ferrous particles. External pole magnets are suitable for the bulk, animal feed, plastics, ceramics and recycling industries.

Robust and low-maintenance design

The automatic external pole magnet is designed to guarantee separation even under harsh conditions, such as in the open air. The housing is completely made of stainless steel and the hinge systems are made of extra thick sheet material. This machine also features a detachable material deflector as standard, which directs the incoming product flow towards the magnets. As a result, iron contamination is captured even more efficiently.

The low installation height of 600 mm makes the system easy to build into existing installations.

Automatic cleaning cycle with collection system

The external pole magnetic separator features an automatic cleaning system. This makes it possible to remotely activate a cleaning cycle during production stops. Ideal for hard-to-reach areas, saving operator time. The magnetic separator is protected by safety caps to protect the magnets, both in the on and off positions.

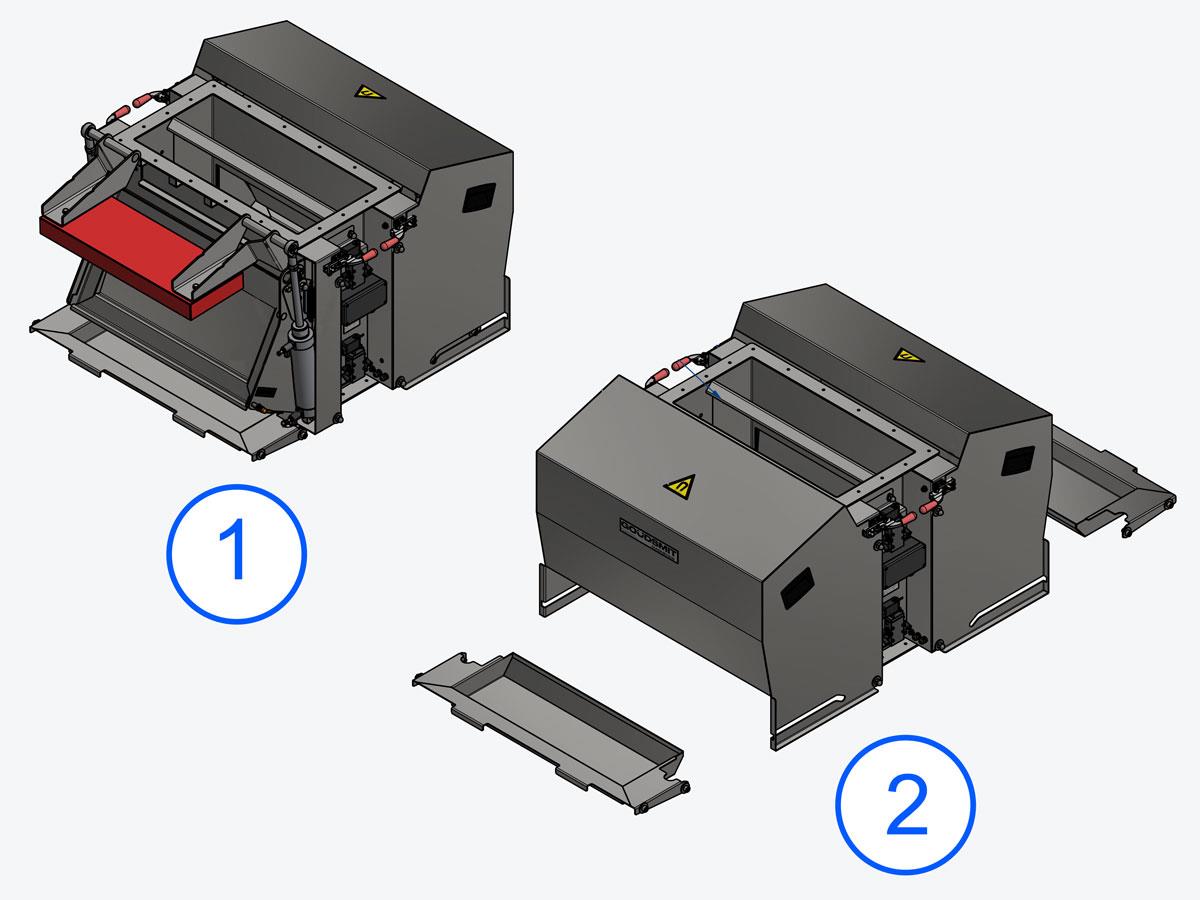

When the cleaning cycle starts, both magnets – including the extractor plate – detach from the product channel. Once in the off position – see figure 1 – the extractor plate detaches from the magnet, after which the captured iron particles fall into both collection trays. During inspection rounds, you can remove the collection trays – see figure 2 – and analyse the captured iron contamination.

Mechanism of the magnet system

You connect the external pole magnet directly to the free-fall chute of your production process. You do this preferably at the beginning of the process in order to remove any iron contamination early. The product flow arrives at the material deflector first. This disperses the particles and guides everything past the two magnetic fields. The powerful neodymium plate magnets capture and retain the iron particles until the cleaning cycle starts.

A pneumatic control takes care of cleaning the magnet. This is started via a 24V-DC signal and then runs fully automatically. During the cleaning cycle, both plate magnets rotate upwards, from vertical to horizontal. When that point is reached, both extractor plates are out of the product flow and free of the magnets. As a result, the iron particles fall from the extractor plates into the collection trays. The magnets subsequently move back into position to capture iron particles again.

The robust external pole magnet filters large ferrous particles of up to 50 mm from free-fall chutes. Very suitable for high-capacity product flows in combination with relatively low installation heights. The plate magnets are placed outside the product channel to guarantee unobstructed product flow. The automatic cleaning makes this system suitable for locations that are difficult to access for maintenance and cleaning.