Hightech industry

High-tech is about miniaturisation, accuracy and effectiveness. This requires customisation in design and production.

Challenges on the high-tech market

The applications of magnets and magnet assemblies in the high-tech industry are endless. However, this also means that increasing demands are being placed on suppliers. As a manufacturer, you face the challenge of innovating and keeping the time-to-market for new developments as short as possible, while maintaining quality, safety and reliability of delivery. At Goudsmit we understand these challenges and are happy to help you.

Rapidly changing technical possibilities

Developments in the field of magnetism and possible applications in high-tech are progressing very fast. For example, there are constantly new possibilities in the field of shapes, magnetisation direction, coating, material composition, strengths and tolerances.

Magnets offer special properties, but require expertise

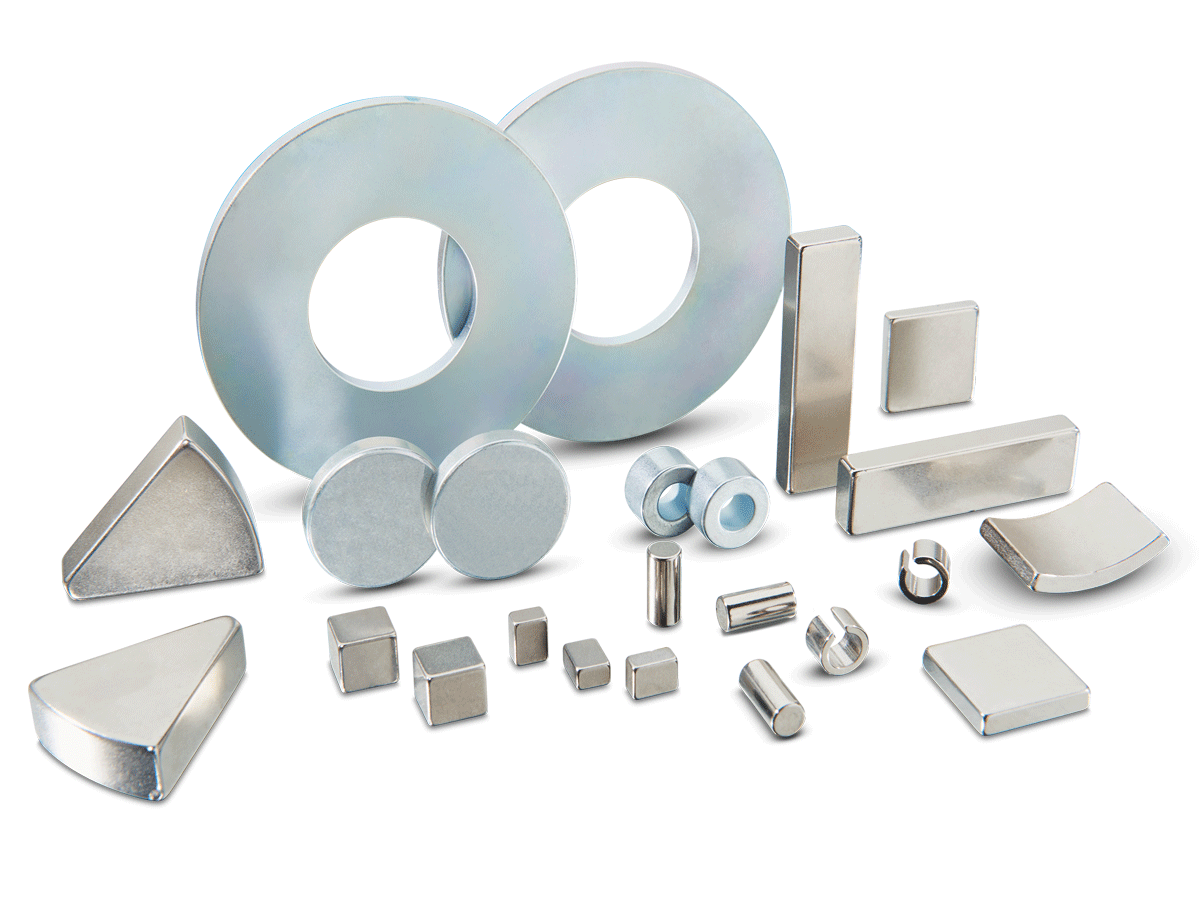

A magnet is much more than a standard component in a high-tech product. Each permanent magnet has unique magnetic properties, tolerances and finishes. This requires a great deal of theoretical knowledge about magnetism, but also experience in production techniques and the manufacturability of products.

Permanent magnets overview

High-tech requires customisation in design and production

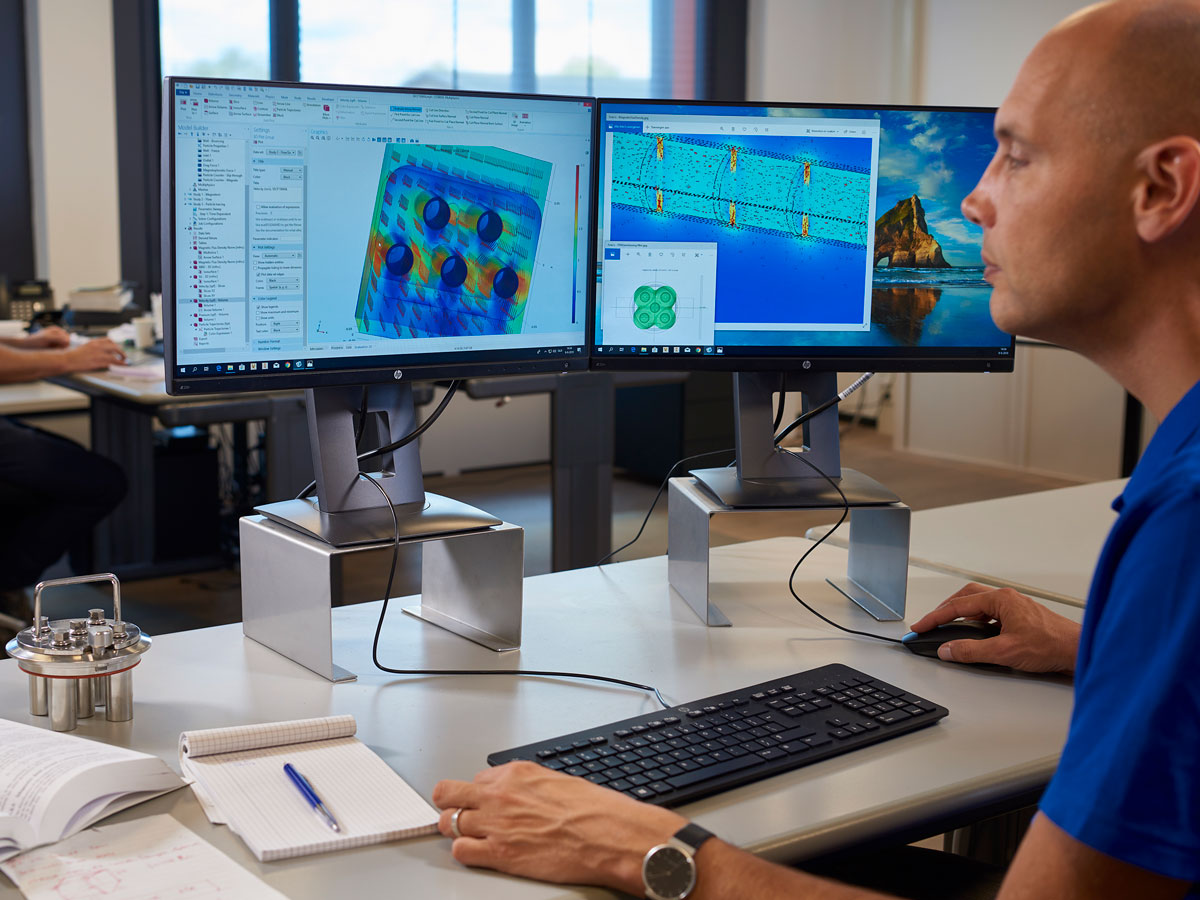

Miniaturisation and effectiveness are the challenges you face. To this end, magnet calculations and simulations are the basis for designing the best magnet system for your application. An incorrect choice or assumption can lead to a poor or non-functioning system.

Magnetic flow simulation

Reliable suppliers in a global production network

Magnets are made from rare-earth metals. Compositions with NdFeB and SmCo also fall into this category. Finding reliable producers can be a challenge, both in terms of material, quality and supporting reports. Moreover, geopolitical tensions regularly cause price instability or poor delivery reliability. The goal is always to deliver as agreed. That’s what we stand for.

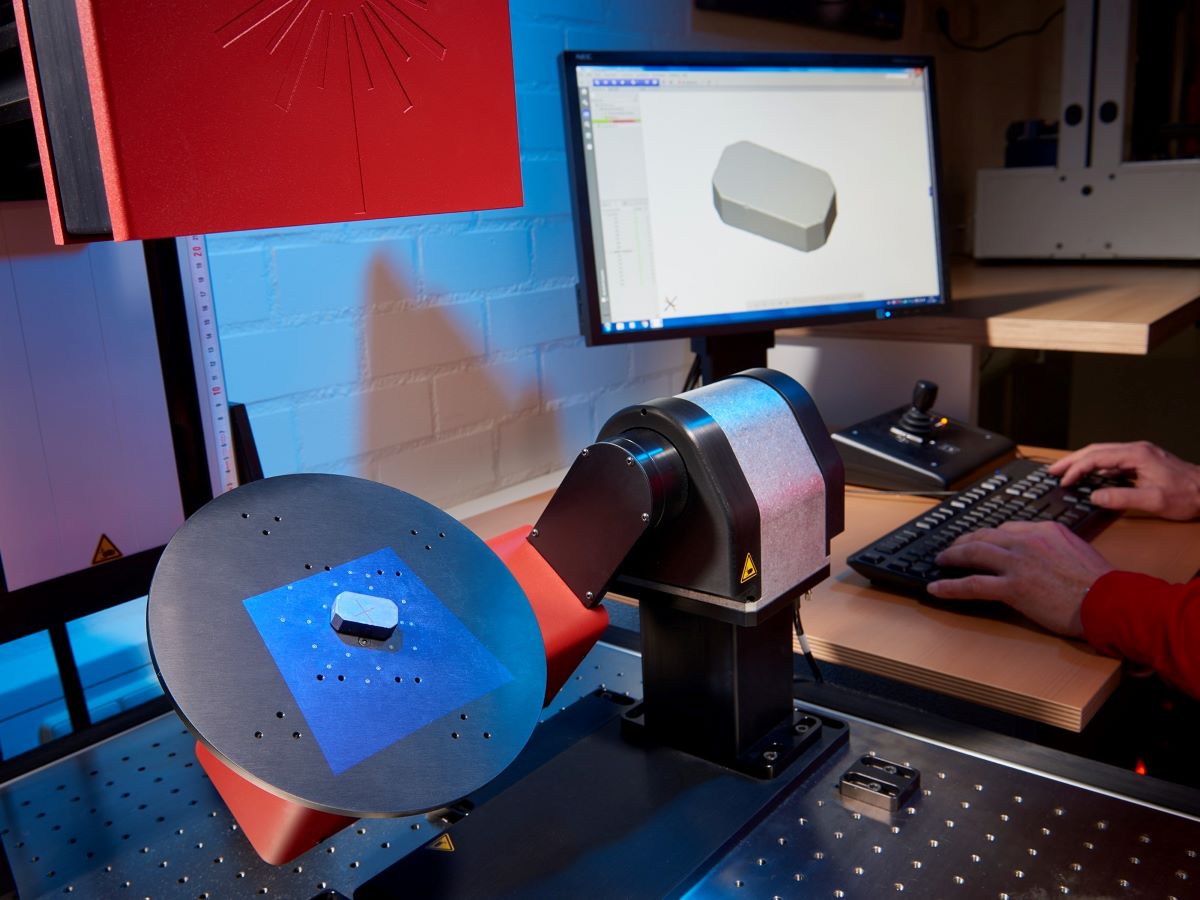

Complex production processes demand a high degree of quality assurance

Flexible numbers and complex manufacturing processes require quality assurance and traceability. For example, the requirements in the high-tech industry require increasingly cleaner and more accurate production environments. And the last thing you want is a recall or production stop due to quality problems.

Always ensure safety

Because magnetic fields are invisible, but very strong, the risk of emergencies is always present. It is important for both man and machine to apply magnets carefully. Especially during transport, packaging and placement of magnets.

This film explains how to work safely with very strong magnets

We are happy to use our specialist skills to help you

Thanks to our years of experience in the magnet industry, we understand your challenges better than anyone else. We will support you with the most complex projects, both during the theoretical phase and the practical implementation. Our team of engineers performs the calculations that lead to the best results and our production is as efficient as possible.

Continuous exploration of technical developments

Our engineers are constantly looking for technical developments to achieve the most challenging shapes, compositions, strengths and tolerances. The challenge here is to apply the technology that suits your time-to-market needs.

All professional knowledge from theory to production in-house

Factors such as manufacturability, cleanliness, sustainability, maintenance and safety determine the success of your product. We have the right people for all these disciplines. We have both scientifically-trained engineers and a wide range of production machines and measuring equipment.

Customised simulations and calculations

Our specialists work with the latest FEM software. We combine fundamental physical knowledge from an analytical approach with the COMSOL simulation tool to set up, perform, analyse and evaluate numerical simulations. This gives you certainty about the function of a magnet or magnet system even before the prototype phase. You can find more information in our white paper “FEM-modelling.pdf”.

Network of suppliers - from Brainport to Asia

We have a carefully constructed network of suppliers in the field of magnets and components for magnet composition in the Brainport region, Europe and Asia. These suppliers are audited regularly, so that we can continue to guarantee and improve quality where possible. Deliveries according to specifications, on schedule and within budget is what we stand for.

Quality assurance according to industry standards

Our quality processes, combined with advanced measuring equipment and skilled people, ensure that our deliveries meet your product and quality requirements on all fronts. We have a conditioned measuring room and control the processes to ensure traceability. We also hold the following certificates:

- ISO 9001

- ISO 14001

- RoHS & REACH

Safety in production and logistics

Because we work with magnets on a daily basis, we know exactly how to prevent accidents and minimise risks. Marking and packaging solutions ensure safety for people and machinery. Moreover, the packaging is designed in compliance with the cleanliness requirements that are so important in the high-tech industry.