Open-pole vs. double-sealed magnetic separators

Why the choice of open-pole or double-sealed magnetic system is important for safety and maintenance.

Magnetic separators are used with an extractor system to remove metal particles from products, for example in the food industry. There are two main types of magnet systems: open-pole and double-enclosed magnet systems. Both systems serve the same purpose, but they work in different ways. It is important to understand why a double-enclosed magnet system is often the better choice, especially when it comes to safety, efficiency and maintenance.

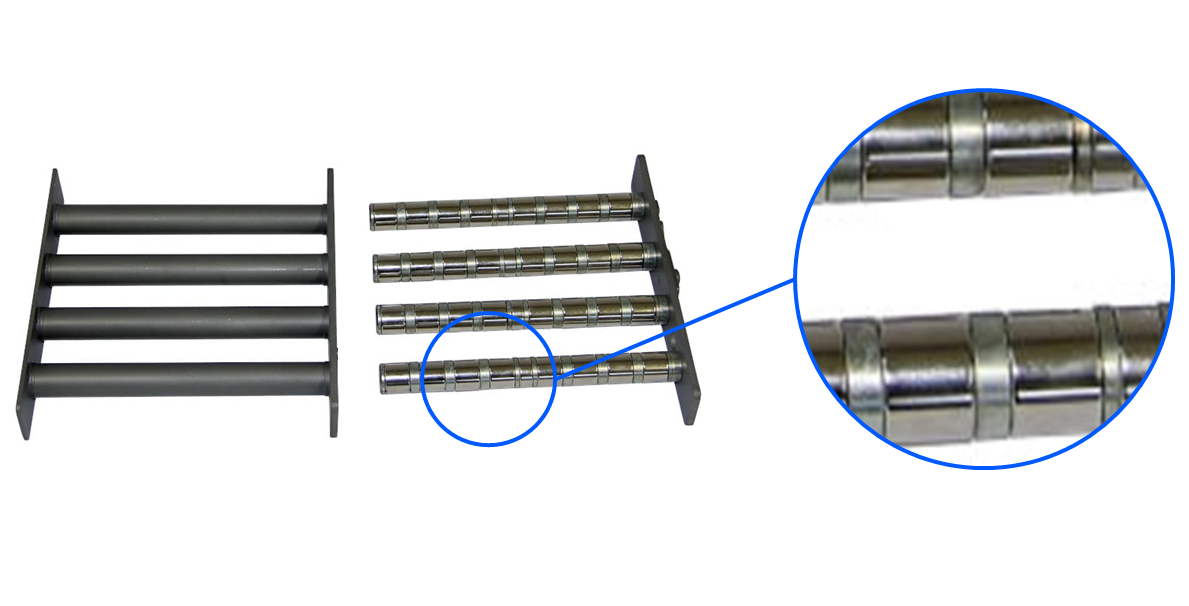

How does an open-pole magnet system work?

In an open-pole system, the magnets slide directly into a tube that makes contact with the product to be cleaned. In this process, the magnets are unprotected. There is then a risk of contaminants getting between the magnets and the tube, which can damage the coating of the magnets or the metal strips. If the coating of the magnets is damaged, they may swell due to moisture or heat, causing them to lose their strength and no longer effectively capture iron. Eventually, the magnet may become stuck in the tube, hindering the operation of the system or even shutting it down completely.

How does a double-sealed magnet system work?

In a double-sealed magnet system, the magnets are enveloped by an extra protective stainless steel tube. This tube forms a watertight seal around the magnets, preventing contamination from coming into direct contact with the magnets or the metal pole strips. The magnets are thus better protected from damage. Cleaning becomes easier because the two smooth surfaces of the tube and extractor slide smoothly into each other, without dirt accumulating or causing damage.

Why is the type of extractor of the magnetic system important?

The main advantage of a double-sealed magnet system is the protection it provides to the magnets. When the magnets are properly protected, they remain clean, powerful and effective. They can be used longer without losing magnetic power. Moreover, cleaning is easier and faster, which is essential in the food industry, for example, where hygiene and efficiency are very important.

The main advantage of a double-sealed magnet system is the protection it provides to the magnets. When the magnets are properly protected, they remain clean, powerful and effective. They can be used longer without losing magnetic power. Moreover, cleaning is easier and faster, which is essential in the food industry, for example, where hygiene and efficiency are very important.

In open-pole systems, damaged magnets and strips can lead to a reduction in the separation effectiveness of the system. If the magnet loses its strength, it becomes more difficult to capture metal particles, which can even lead to product contamination or failure of the entire magnet system. Eventually, the magnets will rust and swell in the extractor, cleaning will no longer be possible.

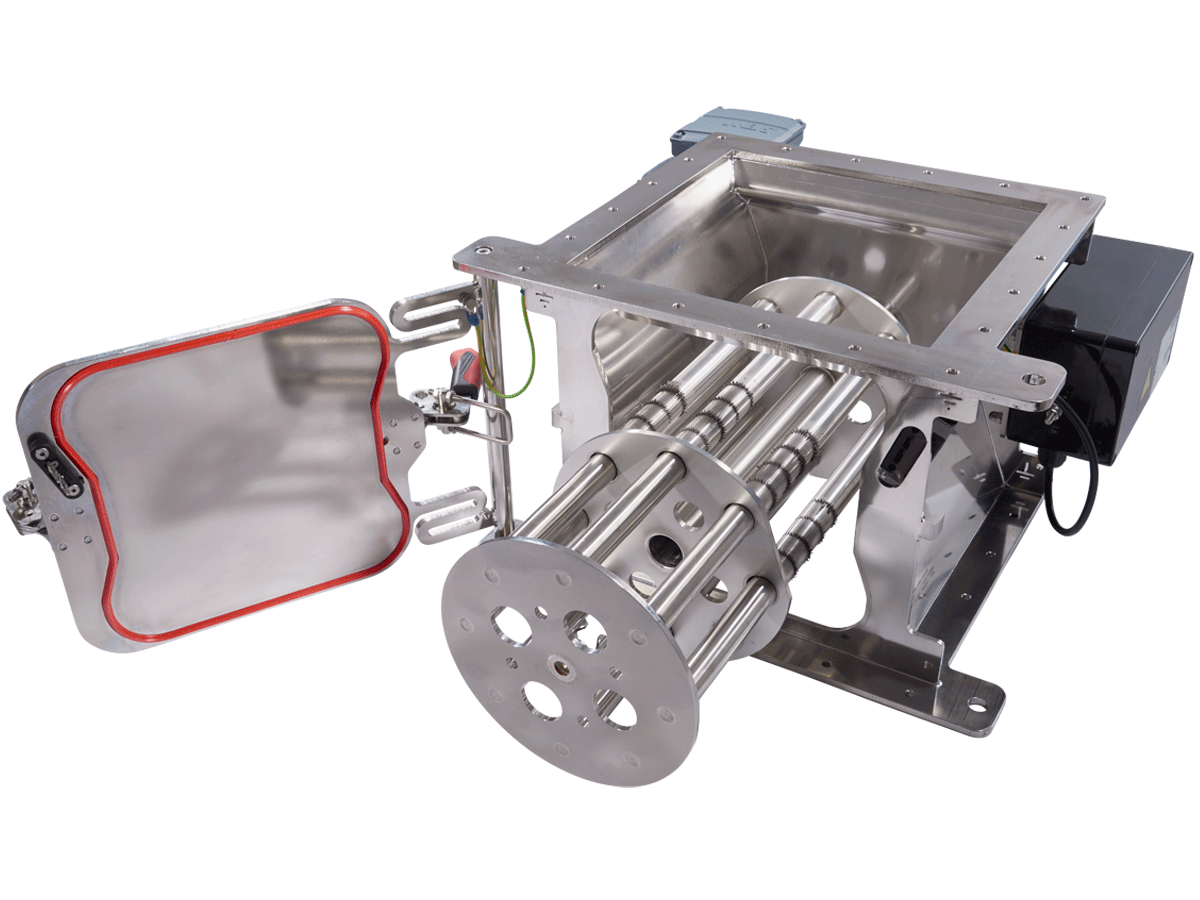

Goudsmit Magnetics' double-enclosed magnet systems

At Goudsmit Magnetics, we always choose the double sealed magnet system. We believe in robust, efficient and easy-to-maintain magnet systems that deliver longer life and reliable performance. That's why we like to invest in additional magnets to still create a strong magnetic field, even if it requires more material. We do this because we focus on long-term customer value. Our goal is to provide our customers with the best solution that is both efficient and safe, with a high level of reliability and minimal maintenance costs.

At Goudsmit Magnetics, we always choose the double sealed magnet system. We believe in robust, efficient and easy-to-maintain magnet systems that deliver longer life and reliable performance. That's why we like to invest in additional magnets to still create a strong magnetic field, even if it requires more material. We do this because we focus on long-term customer value. Our goal is to provide our customers with the best solution that is both efficient and safe, with a high level of reliability and minimal maintenance costs.

The pros and cons at a glance:

| Features | Open-pole extractor | Double sealed extractor |

| Maintenance and cleaning | Harder to clean, accumulation of dirt between magnets and pole plates | Easy to clean due to smooth stainless steel surfaces |

| Life of magnets | Risk of damaging magnets due to contamination during cleaning | Waterproof protected magnets stay effective longer |

| Chance of corrosion | Damaged magnet coating causes magnets to swell and ultimately lead to product failure | Magnet coating is protected by stainless steel tube keeping magnets stable |

| Magnetic field | Fewer magnets needed for the same magnetic field | More magnets needed for the same magnetic field |

| Production | Cheaper to produce | More expensive to produce |

The double-sealed magnet system offers significant advantages over the open-pole system, especially in environments where hygiene, safety, and long-term performance are critical such as the food industry. It offers better protection for the magnets, easier cleaning, and longer system life. At Goudsmit Magnetics, we deliberately choose this system because it contributes to robust, efficient, and sustainable solutions that maximize long-term customer value.

Want to learn more about how our double sealed magnet system can improve your processes? Contact us using the button below.