Magnetic separator types

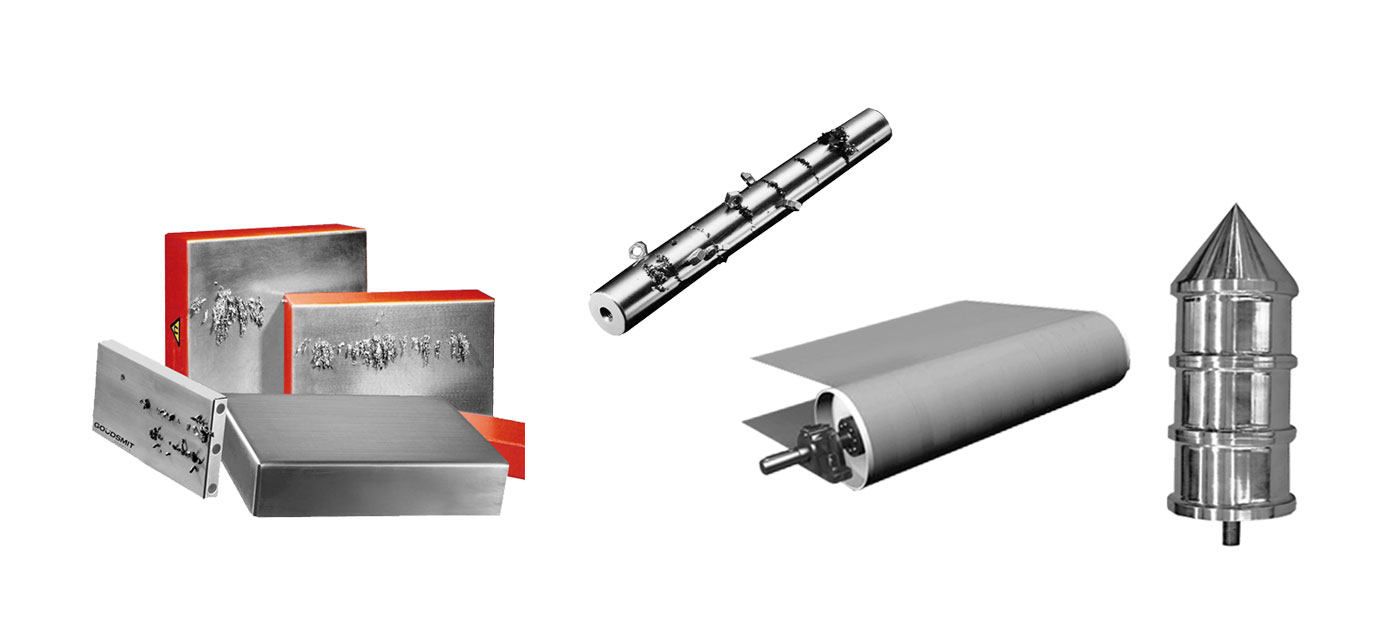

4 magnet systems with specific properties:

Magnetic separator with magnetic plates

The plate magnets are mounted on the outside of the pipe channel. Plate magnets and chute magnets are used in pipeline transport. These systems are always permanently magnetic.

Magnetic separator with suspension magnets

Suspension magnets are large block magnets without or with a band system (overband magnets). They pull metal parts from a material flow on a passing belt. Very suitable for magnetic recycling & sorting. These systems are permanently magnetic or electromagnetic.

Magnetic separators with plate or block magnets have a deeply penetrating magnetic field for capturing ferromagnetic metal particles as small as 1 mm.

Magnetic separators with magnetic bars

Magnetic separators with magnetic bars have an extremely powerful yet less deeply penetrating magnetic field. By placing them in the product channel, they make direct contact with the passing product. Magnetic bar separators are therefore best suited for trapping small ferrous contaminants as small as 30 µm and even weakly magnetic contaminants such as processed stainless steel from bulk flows in filling openings and pipelines.

Magnetic grids, Cleanflow magnets and magnetic filters make use of magnetic bars.

Magnetic separators with cylindrical magnets

Cylindrical magnets are usually found in separators that directly and automatically remove the captured metals. They are therefore capable of separating or sorting large quantities of metal contaminations.

You will find them in:

Recycling & sorting applications:

- robust types of drum magnets

- magnetic head pulleys

- eddy current separators

Filter applications:

- bullet magnets

- drum magnets