Undesired magnetism

Ferromagnetic materials can become undesirably magnetic

Ferromagnetic, also called magnetically conductive materials, such as iron and steel, can very easily become magnetic. Depending on the type of material or alloy, the product remains magnetic. This is referred to as remanent magnetism. Even non-ferritic stainless steel can become magnetic as a result of deformation or during welding.

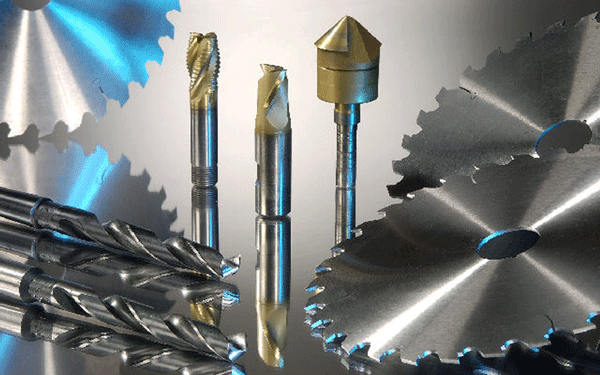

In such cases, the induced magnetism often originates from other magnetic sources such as lifting magnets, clamping tables, loudspeakers or magnetic conveying systems. Magnetic fields near transformers, welding cables and welding processes can also induce magnetism. Furthermore, certain processes such as drilling, grinding, sawing and sanding the material sometimes result in remanent magnetism. Even stainless steel can become undesirably magnetized.

The consequences of residual magnetism can be problematic or even very costly.

A nut that clings to the end of a screwdriver is handy, but two products that stick together in a mould disrupt production, resulting in financial losses. Other possible consequences of undesired magnetism: a coarse surface after galvanization, welds that only adhere on one side, rapid wear of bearings, or metal chips that stick to the parts.

These consequences can be avoided by demagnetizing the material. We supply demagnetization systems and also offer on-site demagnetization of your products. Read more about demagnetization on location or contact us if you have a problem with undesired magnetism.